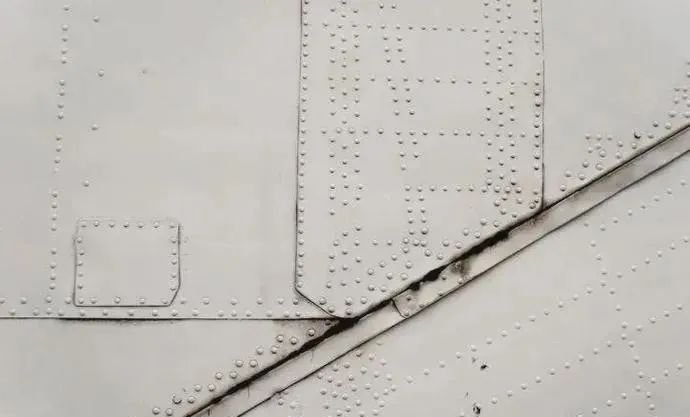

If we look closely at the aircraft, we can see that there are many nails on the skin of the aircraft, such as riveting technology, we often see in some large bridge construction.

There are said to be as many as one million of these rivets on an aircraft — so why not just weld them, but opt for the seemingly cumbersome rivet process?

Strive to reduce the weight of each gram

There is a motto in the aviation industry: “Strive to reduce the weight of each gram.” To reduce the weight of aircraft, aircraft manufacturing will adapt to the use of as light a material as possible.

In order to reduce weight, aircraft skin is usually made very thin. The skin is so thin that it is very difficult to weld them together.

And some aircraft, the fuselage is made of aluminum material, heat resistance is poor, and the welding process in the welding will produce a lot of heat, which is aluminum fuselage of the aircraft, is obviously not appropriate.

Composite materials are widely used in the most advanced airliners in the world. The composite materials will be destroyed by welding. The interconnections of different materials must be fixed by physical means.

The riveting is more stable and reliable

Small make up the first time to take a plane, sitting near the wing window position, when the aircraft encountered turbulence up and down, the wing also occurs obvious shake, then terrible small make up to be frightened…

I believe many friends have seen such a scene, if the turbulence is serious, the aircraft wing will swing up and down significantly.

During this repeated swing, the wing skin is stretched, or squeezed. If a welding process is used, the strength of the weld will decrease significantly under this repeated stress change.

Over time, these areas of welding, it is likely to produce some small cracks, if not found in time, it can be a very big security risk.

The welding seam of civil aircraft is easy to produce metal fatigue problem, and the connection effect is not ideal. Riveting reduces the risk of seismic cracking by reducing the transmission of vibration between the joints. For such repeated stress changes, the fastener is better and more reliable.

Riveting is easy to quantify production, reduce maintenance costs

Welding quality largely depends on the operator’s skills, welding thin welding thickness, randomness is greater, it is difficult to establish a unified standard.

The rivets used in the riveting process, each parameter error is very small, easy to carry out quality control and standardized production.

As we all know, aircraft in the manufacture, the requirements of standardization is very high.

In the aerospace industry, consistency is everything. A plane has millions of rivets, and the first rivets produced must be identical to the next ten million.

This is similar to the large aircraft itself, making an advanced large aircraft for large countries is not too difficult, but the production of tens of thousands of the same products is a great challenge.

Rivets do not increase aerodynamic resistance, but rather reduce it

Some of you may be wondering: will these bulging rivets increase the aerodynamic drag of the aircraft? In fact, the application of the aerospace field of rivets, mainly convex head and countersunk head rivets.

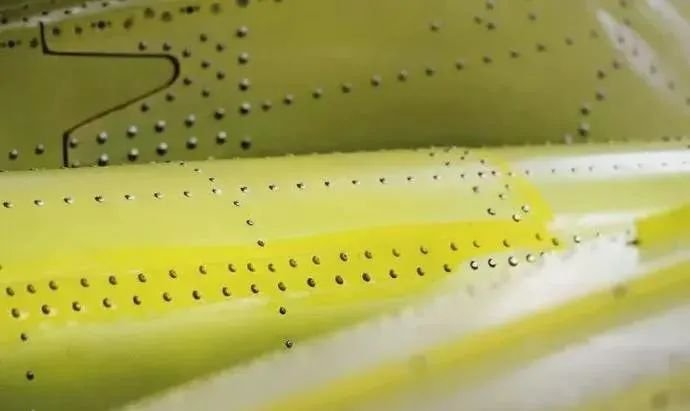

In the aircraft interior, because there is no aerodynamic shape requirements, the main use of low-cost, easy to process the convex head rivets.

The countersunk rivets are mainly used for the smooth parts of the aircraft surface, can effectively reduce the aircraft resistance, the process of processing for the nail cap and the tolerance of nearby structures have strict requirements, when you touch the surface of the aircraft, the rivets are almost imperceptible.

The application has been so successful that, according to World War II data, the aircraft’s resistance can be reduced by about 3% with the use of countersunk rivets.

Scattered parts, through the rivets pin lead, and finally into the sky into a large aircraft. Rivets in the production of aircraft in the unknown, but the most important contribution.