Understanding the Functionality of Clinch Stud Machines

In today’s fast-paced manufacturing world, efficiency and precision are key. That’s where clinch stud machines come into play. These machines are at the forefront of modern welding technology, offering a seamless solution for joining materials. Whether you’re in the automotive, construction, or aerospace industry, understanding how clinch stud machines work can greatly benefit your operations. In this article, we’ll delve into the functionality of clinch stud machines, exploring their components, applications, and advantages.

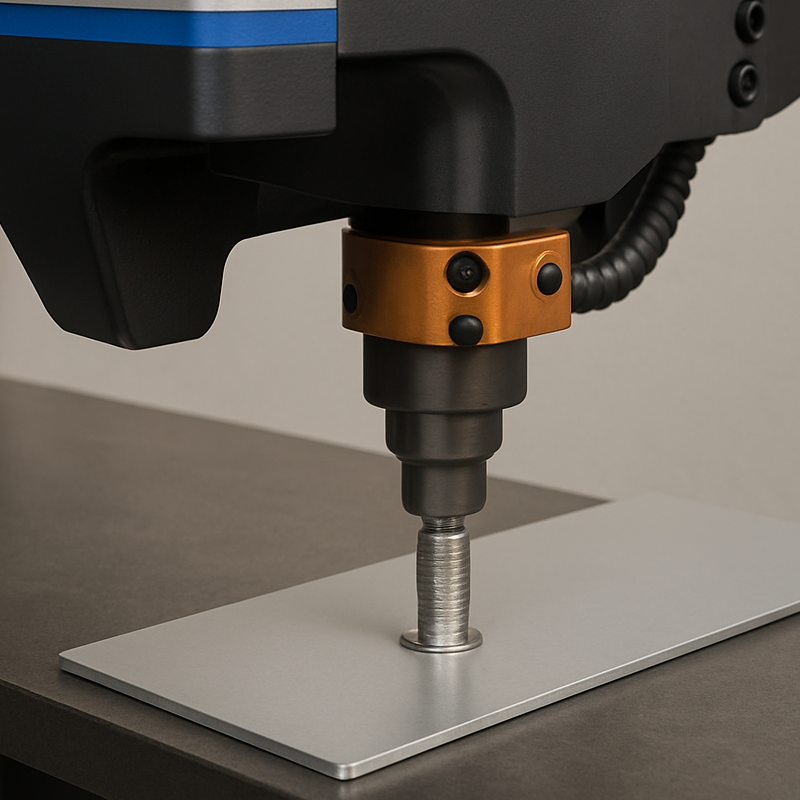

A clinch stud machine is a type of stud welding machine designed to fasten studs to a metal surface without requiring a hole or additional fastening components like bolts or nuts. This technology, known as clinch technology, uses a combination of heat and pressure to secure the stud in place, ensuring a strong and durable joint.

Components of a Clinch Stud Machine

A clinch stud machine consists of several key components:

- Power Source: Provides the electrical energy necessary for the welding process.

- Welding Gun: Holds the stud and applies the necessary force to weld it to the surface.

- Control Unit: Manages the machine’s operations, ensuring precise timing and pressure.

- Base Plate: Supports the metal surface and helps distribute the pressure evenly.

Each component plays a crucial role in the welding process, working together to achieve a secure and efficient joint.

How Does Clinch Technology Work?

Clinch technology relies on a straightforward yet highly effective process. Here’s a step-by-step breakdown:

- Preparation: The metal surface is cleaned and positioned under the welding gun. The stud is loaded into the gun, ready for welding.

- Positioning: The welding gun is aligned with the desired spot on the metal surface.

- Welding: The machine applies a combination of heat and pressure. The heat causes the metal to become malleable, while the pressure forces the stud into the surface, creating a secure bond.

- Cooling: Once the stud is in place, the area is allowed to cool, solidifying the joint.

This process is quick and efficient, making it ideal for high-volume production environments.

Advantages of Clinch Stud Machines

Clinch stud machines offer several advantages over traditional welding methods:

- Speed: The process is fast, enabling rapid production rates.

- Strength: The joints created are exceptionally strong and durable.

- Efficiency: Reduces the need for additional components, minimizing costs and simplifying inventory.

- Versatility: Suitable for a wide range of materials and thicknesses.

These benefits make clinch stud machines a popular choice in various industries.

Applications of Clinch Stud Machines

Clinch stud machines find applications in numerous industries due to their versatility and efficiency. Here are a few examples:

Automotive Industry

In the automotive sector, clinch stud machines are used to attach components such as trim, panels, and brackets. The speed and strength of the joints make them ideal for high-volume assembly lines.

Construction

In construction, these machines are employed to fasten metal studs to structural elements, providing a secure and reliable connection. This is particularly useful in prefabricated building systems where speed and precision are crucial.

Aerospace

In the aerospace industry, where weight and strength are critical factors, clinch stud machines help assemble lightweight components without compromising structural integrity.

Electronics

In electronics manufacturing, clinch stud machines are used to attach components to circuit boards, ensuring a secure and precise fit.

Choosing the Right Clinch Stud Machine

When selecting a clinch stud machine, several factors should be considered to ensure it meets your specific needs:

- Material Compatibility: Ensure the machine can handle the types of materials you’ll be working with.

- Production Volume: Consider the machine’s speed and capacity to match your production requirements.

- Ease of Use: Look for a machine with user-friendly controls and maintenance features.

- Cost: Evaluate the machine’s cost against its features and your budget constraints.

By carefully considering these factors, you can choose a clinch stud machine that enhances your manufacturing operations.

Conclusion

Clinch stud machines represent a significant advancement in welding technology, offering speed, strength, and efficiency to various industries. Understanding their functionality and applications can help you make informed decisions for your manufacturing processes. Whether you’re in automotive, construction, aerospace, or electronics, clinch stud machines can streamline your operations and improve your bottom line. Embrace this innovative technology and stay ahead in today’s competitive market.