Understanding the Functionality of Clinch Stud Machines

Clinch stud machines are revolutionizing the way industries approach fastening solutions. These machines offer a unique method to attach studs to metal sheets without drilling or welding.

Clinch technology is at the heart of this innovation. It mechanically interlocks materials, providing a clean and efficient fastening solution. This process reduces the need for additional finishing, saving time and resources.

Industries like automotive, aerospace, and construction benefit greatly from these machines. They provide a cost-effective and environmentally friendly alternative to traditional welding methods.

Clinch stud machines are designed for high-speed production, enhancing manufacturing efficiency. They handle various materials, including steel and aluminum, making them versatile for different applications.

In this guide, we will explore the functionality, benefits, and applications of clinch stud machines. Discover how they compare to other stud welding technologies and why they are a preferred choice in many industries.

What Is a Clinch Stud Machine?

A clinch stud machine is a specialized device designed to attach studs to metal surfaces without traditional welding or drilling. This machine uses clinch technology, which mechanically interlocks the stud and metal sheet, forming a strong joint.

Unlike conventional methods, clinch stud machines do not require consumables like welding rods. This makes the process more efficient and environmentally friendly. The technology behind these machines is sophisticated but easy to integrate into existing production lines.

Key features of clinch stud machines include:

- Mechanical interlocking of materials

- No need for additional finishing

- Suitable for various materials

Manufacturers often use these machines in situations where access to the reverse side of the workpiece is limited. Their design allows for easy operation and precise control over the fastening process. Ultimately, clinch stud machines help reduce labor and material costs, providing a cost-effective solution for many industries.

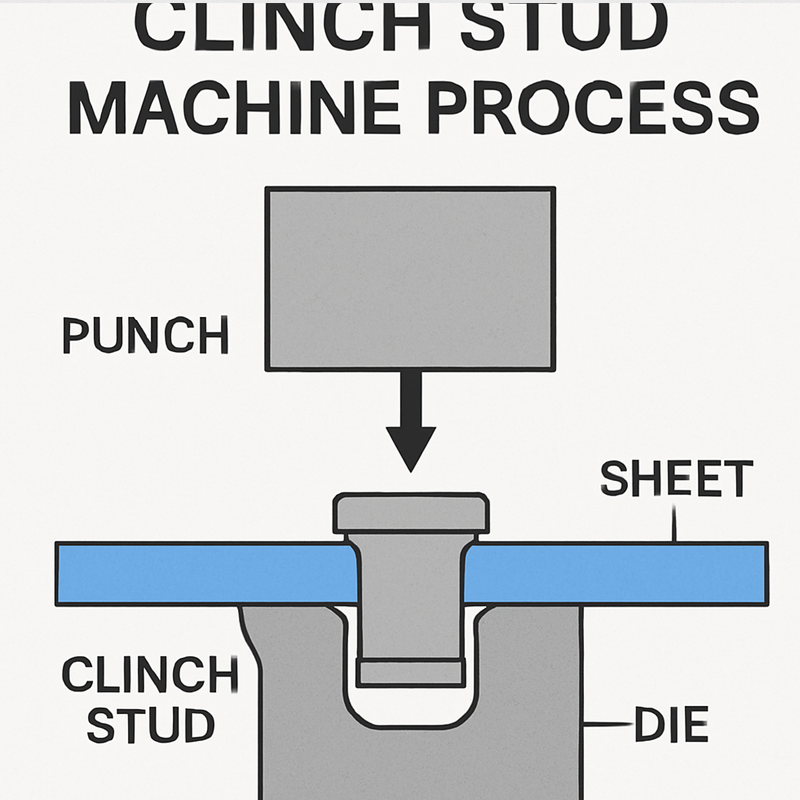

How Clinch Technology Works

Clinch technology is a process involving the mechanical interlocking of materials without the use of heat. It uniquely forms a connection by pressing a stud into a metal sheet to create a joint. This mechanical bond is achieved through the precise application of pressure.

The process begins when the stud is aligned with the metal sheet using the machine’s alignment tools. Force is then applied, driving the stud into the sheet and causing the materials to interlock. This results in a secure bond that does not compromise the integrity of either material.

Key aspects of clinch technology:

- Utilizes mechanical force, not heat

- Creates durable, reliable joints

- Reduces material deformation

In addition to strength, clinch technology is silent and does not emit harmful fumes. The elimination of heat reduces the risk of material degradation or distortion. Moreover, the technology enables high-speed production, making it ideal for automated lines. It provides an efficient and consistent method for fastening studs across different applications.

Key Benefits of Clinch Stud Machines

Clinch stud machines offer numerous advantages over traditional fastening methods. Their ability to operate without heat reduces potential damage to sensitive materials. This aspect makes them particularly suitable for applications in industries like electronics and aerospace.

One significant benefit is the environmental friendliness of the process. Clinch technology eliminates the need for consumables such as welding rods, and it does not produce harmful fumes. This makes it a cleaner and more sustainable option.

Cost-effectiveness is another advantage. These machines lower labor and material expenses by streamlining the production process. They also require minimal maintenance, which further reduces operational costs.

Highlighted benefits include:

- Reduced material costs

- Environmentally friendly process

- Minimal maintenance requirements

Clinch stud machines also excel in providing consistent results. Their precision ensures high-quality joints in every production cycle, enhancing product reliability. Their versatility across various materials and environments makes them indispensable for modern manufacturing.

Applications Across Industries

Clinch stud machines are versatile tools in many sectors, ensuring sturdy and reliable fastening solutions. They excel in automotive manufacturing, where they securely affix components without leaving any marks on finished surfaces. This enhances product aesthetics and durability.

The aerospace industry also benefits from clinch technology. Here, the machines provide lightweight, strong joints crucial for high-performance applications. By minimizing heat exposure, they prevent potential material degradation, which is vital in this precision-driven field.

Numerous other industries utilize clinch stud machines, including:

- Construction

- Electronics

- Appliances

In each, the machines contribute to efficient production processes. They adapt well to various metals and alloys, promoting broader usability. Their role in high-speed production lines further underscores their industrial importance, driving innovation and efficiency across sectors.

Clinch Stud Machines vs. Stud Welding Machines

When choosing between clinch stud machines and stud welding machines, understanding their differences is essential. Clinch stud machines utilize mechanical fastening, avoiding heat. This distinction means no risk of material distortion due to excessive temperatures.

Stud welding machines, on the other hand, rely on heat to create bonds. This can sometimes affect the material’s structural integrity if not managed properly. Each technology serves its purpose based on the project’s specific demands.

Here is how they compare:

- Heat: Clinch – No heat, Welding – Uses heat

- Integrity: Clinch – Preserves, Welding – Potential distortion

- Applications: Clinch – Limited access areas, Welding – Wider access needed

Ultimately, choosing depends on application requirements. Consider factors like material type, production speed, and specific end-use. Whether it’s preserving material integrity or achieving rapid production, understanding both machines ensures optimal decision-making.

Choosing the Right Clinch Stud Machine

Selecting the appropriate clinch stud machine depends on various factors essential for ensuring optimal performance. First, assess the materials you work with to ensure compatibility. Certain machines may handle only specific metals or alloys.

Consider the production volume when choosing a machine. High-speed production lines benefit from machines with rapid cycle times. This requirement ensures efficiency in meeting targets.

Other critical criteria include the machine’s adaptability and integration capability with existing systems. Evaluate the following:

- Material compatibility

- Production speed

- Integration capabilities

Determine whether you need a stand-alone unit or one that fits into an automated line. Matching your needs with the machine’s features can significantly enhance productivity and efficiency in your operations.

Maintenance and Safety Considerations

Proper maintenance is vital for the longevity and performance of clinch stud machines. Regular inspections help identify potential issues before they escalate. Routine checks include evaluating moving parts and ensuring all components are securely fastened.

Safety considerations are equally important. Machines should be operated by trained personnel only. It’s essential to implement safety protocols to protect workers.

Key maintenance and safety tips:

- Perform regular inspections

- Train all operators thoroughly

- Implement and follow safety protocols

By adhering to these guidelines, you can maintain equipment efficiency while ensuring a safe working environment. Prioritizing both maintenance and safety will contribute to the machine’s optimal performance and longevity.

Conclusion

Clinch stud machines play an integral role in modern manufacturing processes. They provide a reliable and efficient method for fastening without the need for heat. This makes them ideal for industries where material integrity must be preserved.

By understanding the benefits and applications of clinch technology, businesses can make informed decisions on incorporating these machines into their production lines. Their use not only enhances productivity but also supports sustainable practices with reduced energy consumption and minimal environmental impact. Embracing clinch stud machines offers a path to innovative and eco-friendly manufacturing solutions.