Understanding Clinch Stud Standards in Manufacturing

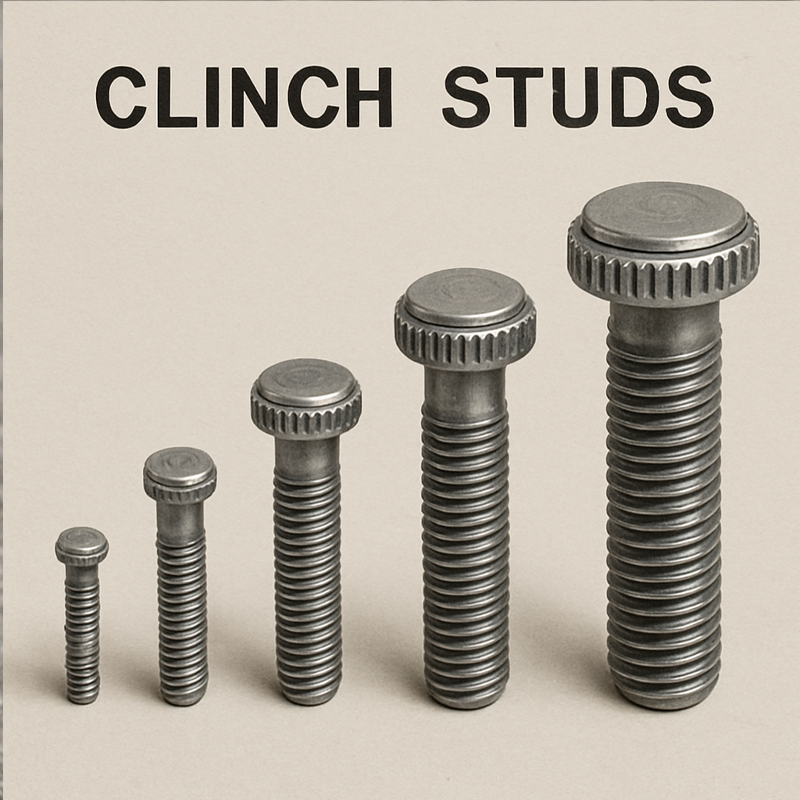

In the realm of manufacturing, the quest for efficiency and precision is never-ending. One small yet crucial component in this process is the clinch stud. These seemingly insignificant fasteners play a vital role in various applications, ensuring that components remain secure and function as intended. To fully harness their benefits, it’s essential to understand clinch stud sizes, standards, and installation processes.

A clinch stud is a type of fastener designed to be permanently attached to a metal sheet, providing a strong and reliable threaded anchor. They are commonly used in sheet metal fabrication, automotive manufacturing, and electronic enclosures. By embedding the stud into the metal sheet, manufacturers can achieve a secure fit that withstands high levels of stress and vibration.

The Importance of Clinch Studs

Clinch studs are crucial in applications where space is limited, and traditional fastening methods are not feasible. They offer several advantages, including:

- Space Efficiency: Clinch studs provide a low-profile solution that does not protrude from the surface, making them ideal for compact assemblies.

- Strength and Durability: Once installed, clinch studs offer high resistance to torque and shear forces, ensuring longevity.

- Consistency: They provide uniformity in assemblies, making them reliable across various applications.

Understanding Clinch Stud Sizes

Clinch studs come in a variety of sizes to suit different applications. Understanding these sizes is key to selecting the right stud for your project. The size of a clinch stud is determined by its diameter and length, which are typically specified in inches or millimeters.

Diameter

The diameter of a clinch stud is the primary dimension that defines its size. It determines the thickness of the material that the stud can be installed into. Common diameters range from as small as 1/8 inch (3 mm) to over 1/2 inch (12 mm).

Length

The length of the clinch stud is another critical dimension. It is measured from the base of the stud to the end of the threaded portion. Lengths can vary significantly based on the application, with options ranging from short studs for thin materials to longer studs for thicker assemblies.

Clinch Stud Standards

To ensure compatibility and consistency, clinch studs are manufactured to specific standards. These standards define the dimensions, materials, and performance characteristics of the studs. Here are some commonly referenced standards:

ISO Standards

The International Organization for Standardization (ISO) sets global benchmarks for various industrial components, including clinch studs. ISO standards ensure that clinch studs meet specific quality and performance criteria, facilitating international trade and compatibility.

ANSI Standards

In the United States, the American National Standards Institute (ANSI) provides guidelines for clinch stud manufacturing. These standards cover aspects such as thread dimensions, material specifications, and installation requirements.

Manufacturer Specifications

Many manufacturers offer their own specifications for clinch studs, which may include proprietary features or enhanced performance characteristics. While these may not align perfectly with ISO or ANSI standards, they often provide additional benefits suited to specific applications.

Clinch Stud Installation

Proper installation is crucial to achieving the full benefits of clinch studs. The process involves embedding the stud into the metal sheet using specialized equipment. Here’s a step-by-step guide to installing clinch studs:

Step 1: Preparation

Before installation, ensure that the metal sheet is clean and free from contaminants. The surface should be flat and smooth to allow for a secure fit.

Step 2: Hole Drilling

Drill a hole in the metal sheet where the clinch stud will be installed. The hole’s diameter should match the stud’s specifications to ensure a snug fit.

Step 3: Stud Placement

Position the clinch stud in the drilled hole. Ensure that the stud is aligned perpendicular to the metal sheet for optimal performance.

Step 4: Pressing

Use a press or similar equipment to embed the stud into the metal sheet. Apply consistent pressure to ensure the stud is fully seated and flush with the surface.

Step 5: Verification

After installation, verify that the stud is secure and properly aligned. Check for any signs of deformation or misalignment that could affect performance.

Choosing the Right Clinch Stud

Selecting the appropriate clinch stud for your project involves considering several factors:

Material

Clinch studs are available in various materials, including stainless steel, aluminum, and brass. The choice of material depends on factors such as corrosion resistance, strength, and weight.

Application

Consider the specific requirements of your application, such as load capacity, environmental conditions, and space constraints. This will help determine the suitable size and material for the clinch stud.

Compatibility

Ensure that the clinch stud is compatible with the metal sheet’s thickness and material. This will ensure a secure fit and reliable performance.

Conclusion

Understanding clinch stud standards, sizes, and installation processes is essential for manufacturers seeking efficient and reliable fastening solutions. By choosing the right clinch stud and following proper installation procedures, you can enhance the strength and durability of your assemblies, ensuring optimal performance in various applications.

Whether you’re working in automotive, electronics, or any other industry, clinch studs offer a versatile and dependable solution for your fastening needs. With the right knowledge and tools, you can leverage these small yet mighty components to achieve big results in your manufacturing projects.