Understanding Clinch Stud Standards in Manufacturing

Clinch studs play a vital role in manufacturing. They are essential fasteners used to attach components to thin metal sheets.

These studs are prevalent in industries like automotive, aerospace, and electronics. Their reliability and strength make them indispensable in these fields.

Understanding clinch stud standards is crucial for ensuring compatibility and performance. These standards guide the selection and installation of clinch studs.

Proper installation is key to maintaining the integrity of the assembly. Incorrect installation can lead to failures, compromising the entire structure.

This guide will explore clinch stud standards, sizes, and installation processes. It aims to educate professionals and students in mechanical engineering and related fields.

What Are Clinch Studs?

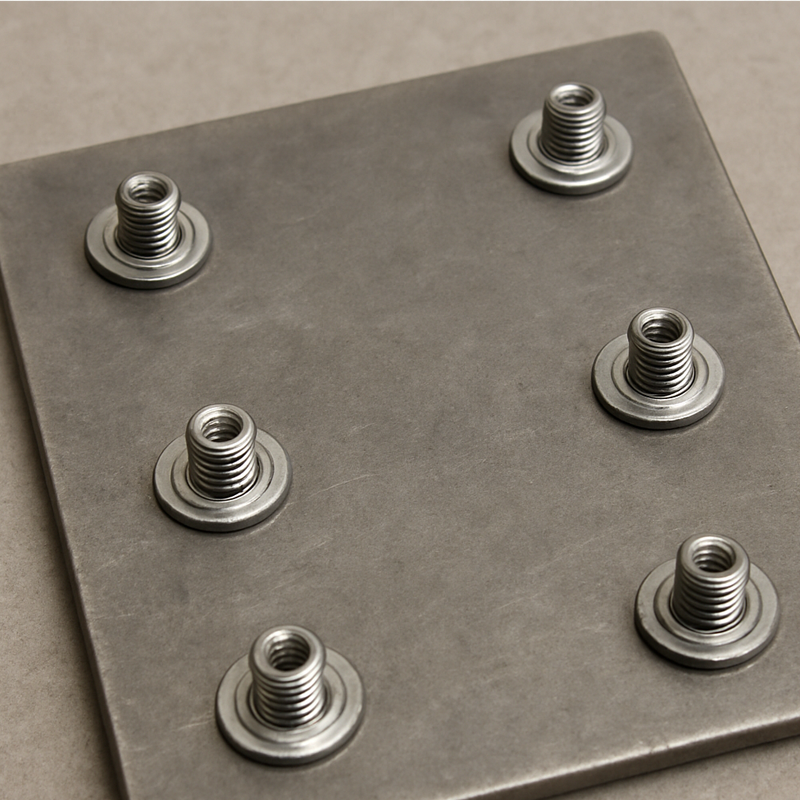

Clinch studs are specialized fasteners designed to attach components securely to thin sheets of metal. They are pressed into pre-punched holes, creating a strong hold without the need for additional hardware.

These studs are typically used in environments where traditional welding or rivets might not be feasible. Their unique design allows them to provide a flush finish, which is important for both aesthetic and practical reasons.

Clinch studs come in various forms tailored to specific needs. Here are some key types:

- Self-clinching studs for general applications

- Flush-head studs for smooth surfaces

- Floating clinch studs for adjustable fittings

Each type of stud offers distinct features to address different requirements in manufacturing. They accommodate a wide range of loads and vibrations, making them suitable for diverse applications in various industries.

Importance of Clinch Stud Standards

Standards for clinch studs are crucial in manufacturing because they ensure consistency and quality. These standards define dimensions, materials, and performance criteria, making sure that studs work effectively in various applications.

Adherence to these standards allows manufacturers to produce parts that are compatible and reliable, reducing the risk of assembly failures. Standards also help in maintaining the integrity of the finished product by specifying essential characteristics needed for optimal performance.

Key benefits of standardized clinch studs include:

- Improved manufacturing efficiency

- Consistent product quality

- Enhanced compatibility across different applications

By understanding these standards, engineers can choose the right type of clinch stud, ensuring the assembly’s strength and reliability. Consequently, proper standards help in reducing costs and preventing complications during installation and use.

Common Clinch Stud Sizes and Materials

Clinch studs come in a variety of sizes, tailored to meet diverse application needs. The size of a clinch stud typically depends on factors like material thickness and load requirements. Ensuring the correct size is vital for optimal performance and safety.

The sizes range from small dimensions, suitable for delicate electronics, to larger sizes used in heavier structures. Engineers often rely on specified charts to select the appropriate stud size, which helps in achieving a secure fit.

Material selection is another crucial aspect of clinch studs. Common materials used include:

- Steel

- Stainless Steel

- Aluminum

Each material offers unique benefits. Steel provides strength, while stainless steel offers corrosion resistance. Aluminum is chosen for its lightweight properties. The selection process involves balancing these attributes against application-specific demands, such as environmental conditions or load capacity.

Understanding these variations allows manufacturers to make informed decisions, resulting in enhanced performance and durability. Clinch studs need to meet the requirements of specific applications, ensuring longevity and reliability in diverse environments.

Clinch Stud Installation Process

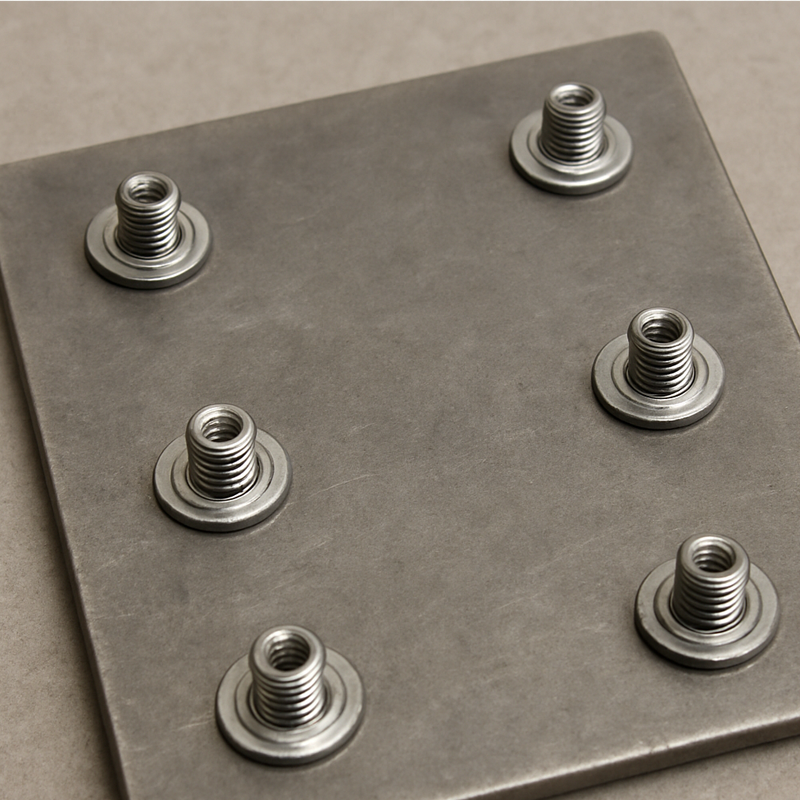

The installation of clinch studs is a critical phase that requires precision. A proper installation ensures the fastening strength and longevity of the assembly. The process involves several key steps that must be followed with care.

Firstly, a hole is punched in the metal sheet to accommodate the stud. The hole size must match the stud’s specifications precisely. A mismatched size can lead to installation failures.

Next, the stud is positioned into the pre-punched hole. This step is crucial as it establishes the foundation for the clinching process. Proper alignment is essential for the integrity of the fastening.

A press or specialized tool is used to install the stud. This tool applies the necessary force to create a secure bond. The pressure causes the material around the hole to flow, anchoring the stud firmly in place.

Key steps in the installation process include:

- Preparing the metal sheet with a precise hole.

- Positioning the clinch stud accurately.

- Utilizing appropriate tools for pressing the stud.

Consistently following these steps leads to a successful installation. Proper technique ensures that the stud withstands operational stresses and contributes to the overall assembly’s reliability.

Key Factors in Selecting the Right Clinch Stud

Choosing the correct clinch stud can significantly impact the assembly’s performance. Many factors must be considered to ensure optimal outcomes. Each factor plays a distinct role in the selection process.

The load requirements are paramount in choosing a clinch stud. Depending on the application, the stud must support varying weights and forces. Failure to meet these requirements can lead to structural failures.

Other considerations include environmental conditions and material compatibility. Exposure to moisture or chemicals may require corrosion-resistant materials like stainless steel. Similarly, the choice of stud material should align with the sheet metal’s properties to prevent issues such as galvanic corrosion.

Key factors to consider are:

- Load requirements and operational conditions

- Environmental exposure and potential chemical interactions

- Compatibility of materials between stud and sheet metal

By focusing on these factors, one can select a clinch stud that ensures efficient, durable, and safe applications.

Applications and Benefits of Clinch Studs

Clinch studs serve a multitude of applications across various industries. Their versatility and reliability make them an essential component in manufacturing. They are particularly prevalent in sectors like automotive, aerospace, and electronics, where high-load conditions are frequent.

One of the main benefits of using clinch studs is their ability to provide a flush finish. This feature is crucial for both aesthetic and functional reasons, particularly in applications where space is limited. They also contribute to reducing assembly time and costs, offering an efficient solution compared to traditional fastening methods like welding.

Key benefits of clinch studs include:

- Compatibility with thin metal sheets

- Ability to withstand high loads and vibrations

- Cost-effective and time-saving in assembly

Their unique design and performance capabilities mean that clinch studs remain an ideal choice for situations where other fastening methods are unsuitable.

Best Practices and Maintenance Tips

Ensuring the durability and effectiveness of clinch studs starts with proper installation and maintenance. Consistently following best practices minimizes the risk of assembly failure and extends the lifespan of your components.

Regular inspections can prevent potential issues, such as loosening or corrosion. It is essential to address any signs of wear promptly to maintain the integrity of the assembly.

Here are some key maintenance tips:

- Conduct periodic inspections for signs of wear

- Use proper tools and techniques during installation

- Replace any damaged or corroded studs immediately

By adhering to these guidelines, you can ensure the reliability and longevity of clinch studs in various applications.

Conclusion

Understanding clinch stud standards is crucial for ensuring reliable and efficient manufacturing processes. These fasteners offer practical solutions for attaching components to thin metal sheets. By selecting the right size and material and following proper installation techniques, manufacturers can achieve strong, durable assemblies that meet industry demands.