In the process of sheet metal parts, it is common to press riveting stud, screw, or nut on the sheet metal parts to meet the use function of the parts. In addition to stainless steel, the surface of most sheet metal parts needs plating treatment, pressure riveting fasteners electroplating, easy to lose, fall off, and other phenomena, that affect the quality of pressure riveting.

And some sheet metal parts such as bending and then pressure riveting, pressure riveting space constraints and not convenient to operate. Through the analysis and research on the press-riveting process of various sheet metal parts, the problem of limited press-riveting space of some sheet metal parts is solved.

Technological analysis of riveting fasteners

The common types of riveting fasteners are riveting studs, riveting screws and riveting nuts, etc. . The installation principle is the same, mainly through the pressure of the riveting parts of the withdrawal groove thread or embossing teeth into the preset holes of the sheet metal parts, plastic deformation occurs at the periphery of the hole, and the deformation is pushed into the guide groove to produce a locking effect.

In the process of surface plating (such as galvanizing, nickel plating, etc.), the locking parts in the guide groove of pressure riveting will be corroded by the solution, which will cause the pressure riveting parts to fall off, should in the process of overall analysis before processing, will affect the quality of the riveting process, riveting operation before the completion of the riveting to ensure the firmness of the riveting parts.

In the use of riveting fasteners, although the installation method and principle have been determined, but still need to use special riveting equipment to operate, this is also an indispensable factor to ensure the stable working performance of the press rivets after installation. When installing, the head of the riveting press and riveting parts should be kept vertically balanced and evenly pressed.

The processing strategy of sheet metal press rivets

1, stainless steel sheet metal parts because there is no electroplating process, for the flat and simple shape of the sheet metal parts need pressure riveting, only after finishing the shape of the workpiece, directly drill preset hole pressure riveting can be. It should be noted that the diameter of the pre-drilled hole should be slightly smaller than the embossed teeth of the riveting fastener, and the size of the bottom hole should be machined according to the tolerance size of 0 ~ + 0.075 mm.

Installation should be achieved by pressing riveting operations, must not be knocked into the impact. For the stainless steel parts that need to be bent and formed, if there is press riveting space after bending, then press riveting can be done after bending to facilitate bending operation; if the parts are more complex, then press riveting can not be done after forming, the riveting press must be adjusted before the bending process.

2. Plating sheet metal parts, the sheet metal parts with simple shape for the sheet metal parts with a simple shape, the method of pressing and riveting is similar to that of stainless steel sheet metal parts, just pay attention to drill the pressing and riveting bottom hole well before plating, after finishing the plating, install the press rivets.

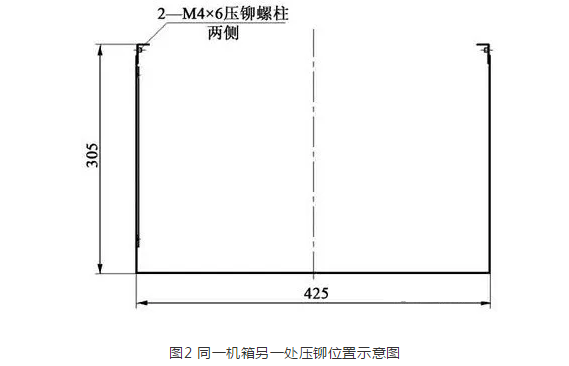

3. Sheet metal parts with limited press-riveting space, take a certain case as an example, its press-riveting position is shown in Figure 1 and Figure 2.

The cabinet is made of Q235 with a plate thickness of 1.5 mm. The main processes are bending, welding, electroplating, and painting. From the above analysis, the part of the riveting process should be arranged in the electroplating process after completion. But after the part electroplating, has bent the welding molding, causing the pressure riveting space to be limited.

In view of the above problems, after analysis and research, the processing strategy is to adopt welding technology, change the riveting stud to a welding steel stud, which can avoid the riveting stud from being corroded by electroplating solution, and because the welding steel stud is of the same material as the chassis, it can be galvanized together with the case after machining, and the stud also gets the corresponding anti-rust treatment, which effectively solves the stud installation problem of this kind of sheet metal parts.

Specific processing technology as follows:

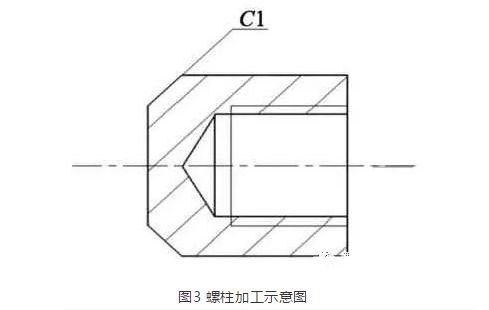

- Q235-A bar, according to the length of riveting stud and the depth of internal thread, turning the same size of steel stud, at one end of the stud edge inverted c 1 bevel (see Figure 3);

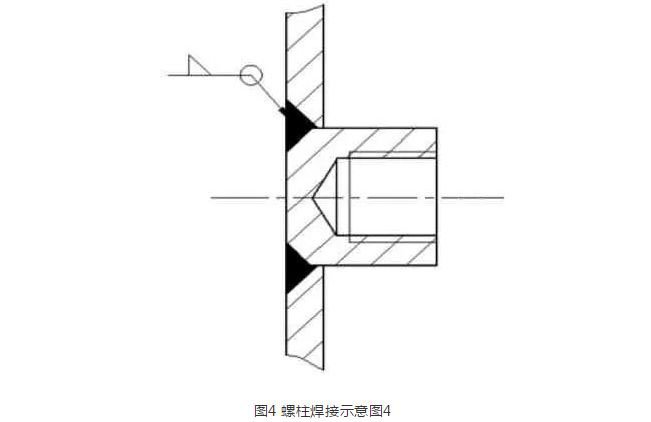

- According to the steel stud outer circle, in the chassis installed position with drilling bottom hole, and sink hole;

- Processing chassis appearance;

- According to the bottom hole position, the steel stud welding on the chassis (see Figure 4);

- Chassis surface welding scar grinding level; 06 cases galvanized, painting.