Self-riveting fasteners are a type of hardware component commonly used in a variety of industrial applications. These fasteners are designed to provide a permanently reliable way to attach components to thin metal panels. They are widely used in the automotive, electronics, and aerospace industries, among others. In this article, we’ll explore the applications of self-clinching fasteners, what they are, and how to install them.

What are self-pressing fasteners?

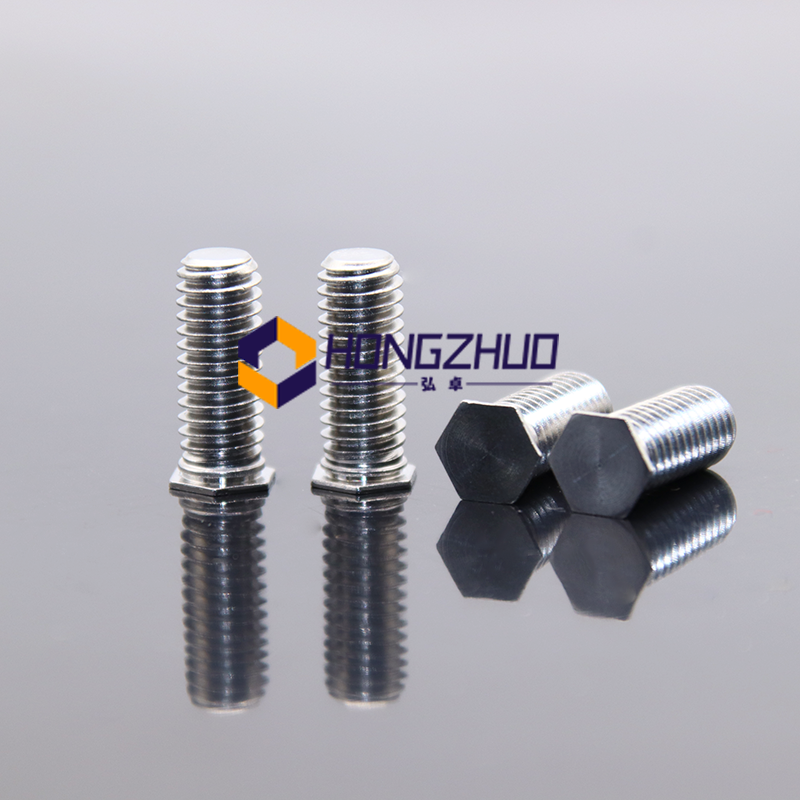

Self-riveting fasteners are threaded nuts, studs, and standoffs designed to be permanently mounted on metal panels. They feature a unique design that allows for easy installation in pre-punched or drilled holes. Once installed, the fastener becomes a permanent part of the panel or frame and provides a strong, reliable thread for mating hardware.

These fasteners come in many types, including stand nuts, stand studs, and stand posts. They are typically made from materials such as stainless steel, carbon steel, and aluminum, and come in a variety of sizes and thread configurations to suit different applications.

Self-pressing fastener applications

Self-riveting fasteners are widely used in applications that require joining components to thin metal sheets. Some common applications include:

- Electronic enclosures: Self-compressing fasteners are often used to secure components such as circuit boards, connectors, and cable management devices to the metal enclosures of electronic equipment.

- Automotive Assembly: In the automotive industry, self-riveting fasteners are used to secure various components such as brackets, clamps, and sensors to sheet metal panels and frames.

- Industrial Equipment: These fasteners are used in the assembly of industrial machinery such as control panels, cabinets, and enclosures that require secure and permanent connections.

- Aerospace: Self-pressing fasteners are used in the manufacturing of aircraft and aerospace equipment, providing a reliable method for connecting components to thin metal structures.

How to install self-pressing fasteners

Installing self-riveting fasteners requires the use of special tools designed for this purpose. This tool, known as a self-clinching fastener tool or press, is used to apply the necessary force to securely install the fastener to the metal plate.

The installation process typically includes the following steps:

- Prepare the mounting holes: Make sure the holes in the metal plate are clean and free of any debris or burrs that could interfere with the installation process.

- Locate fasteners: Place self-riveting fasteners into pre-drilled or punched holes in the metal plate, making sure they are properly aligned.

- Apply pressure: Use a self-riveting fastener tool to apply controlled force to the fastener, causing it to deform and rivet into the sheet metal.

- Inspect installation: After fasteners are installed, inspect the assembly to ensure fasteners are securely installed and threads are formed correctly. In summary, self-riveting fasteners are a versatile and reliable solution for securing components to thin metal sheets in a variety of industrial applications. Understanding their application and installation processes is crucial to ensuring their effective use in different projects.