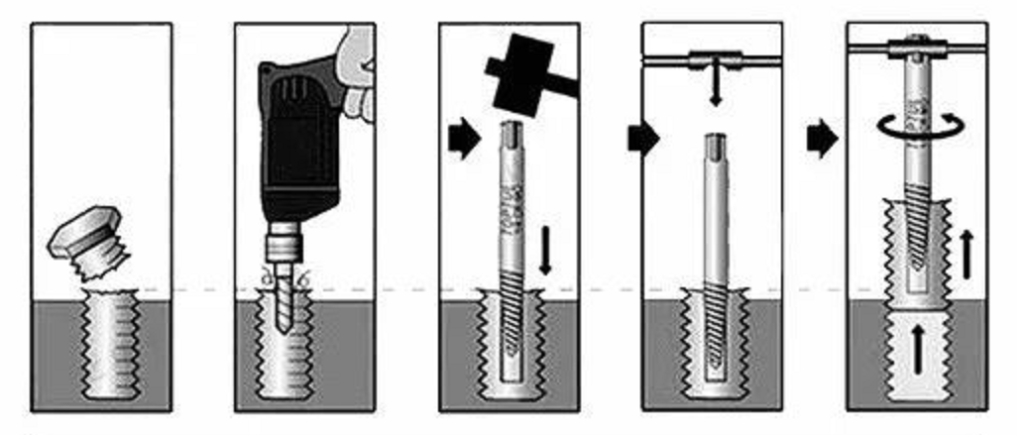

Clinch Studs and bolts are common parts of mechanical equipment, mainly used to link a variety of parts. But in the use of the process, sometimes there will be a break. In that case, what method can be skillfully taken out of the pressure-breaking clinching screws or bolts?

Cleaning sludge and drilling holes with electric drills

- Firstly, the sludge on the surface of the broken head of the pressure-breaking riveting screw is removed;

- Use the center spear to kill the cross-section center spear;

- Then use an electric drill with a 6-8 mm diameter bit to drill the hole in the center of the cross-section (make sure the hole is penetrated) ;

- After the hole is drilled, remove the small bit and replace it with a 16mm diameter bit to enlarge and drill the hole of the broken bolt.

Surfacing

- Take the electrode with a diameter less than 3.2 mm, use small and medium current to carry out surfacing welding from inside to outside in the drilling hole of the broken bolt, and take half of the whole length of the broken bolt at the beginning of the surfacing welding, when starting surfacing, the arc should not be too long to avoid burning through the outside wall of the broken bolt;

- Surfacing to the upper end of the broken bolt and then continue surfacing welding out of a diameter of 14-16 mm high 8-10 mm cylinder

- After surfacing, hammer the end face with a hand hammer to make the broken head bolt vibrate along its axial direction; As a result of the heat generated by the arc and the subsequent cooling coupled with the vibration at this time will broken bolts and the body of the thread between the loose.

- Careful observation, when found after striking a trace of rust leakage from the fracture, can take the M18 riveting nut on the pile on top of the pile and weld the two together.

- After welding cool while hot with the spanner gloves on the pressure riveting nut column around to twist can also twist the side with a small hand hammer to hit the pressure riveting nut column face so that the bolt can be taken out of the broken.

- After removing the broken bolt, process the thread inside the frame with a suitable tap to remove the rust and other sundries in the hole.