Thread connection is one of the four common connection modes (thread connection, welding, riveting, and viscose connection) between automobile parts, which has the advantages of high precision, convenient assembly and disassembly, at present, the main assembly technology of automobile parts is also the most standardized mechanical parts.

The failure of thread connection is one of the frequent failures of the machine, and it is also an important reason for the failure of the whole machine.

Therefore, how to correctly use tightening technology, and reasonable control of Assembly torque is the major OEM new vehicle development process of the important work.

一 、Mechanism analysis of bolt fastening

1. The essence of torque control

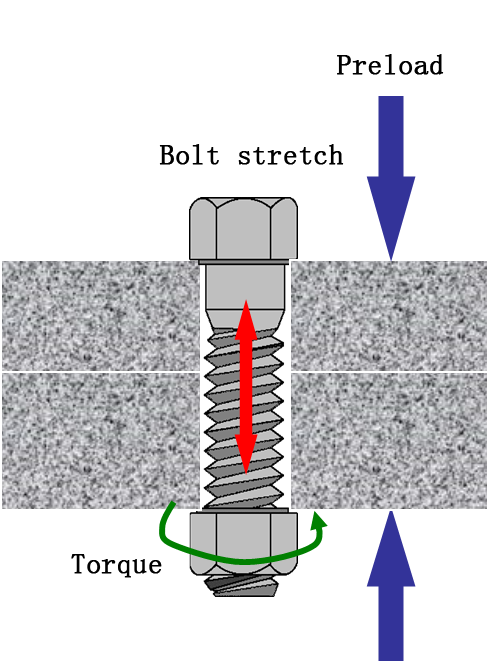

The basic aim of thread connection, especially the important thread connection which bears the dynamic load, is to use the threaded fastener to connect the connected parts reliably. The essence of assembly tightening, or assembly torque control, is to control the axial pre-tightening force of the bolt in an appropriate range.

When a bolt is inserted into a connected part, the bolt is stretched and deformed by tightening with a nut or internal thread. This elastic deformation produces an axial tension that squeezes the clamped parts together, called a preload.

In theory, the greater the axial preload, the better its anti-loosening and anti-fatigue performance, when the preload reached or close to the yield strength of the bolt the best effect.

2. The relation between preload and torque

The torque method is to control the axial preload indirectly by controlling the assembly tightening torque. There is a basic relationship between the tightening torque m of the bolt and the axial pre-tightening force F of the Bolt as follows:

M=KDF

M-tightening torque, K-torque coefficient, F= pre-tightening force, D is the nominal diameter of the thread.

In the experience design, the torque coefficient k value usually takes 0.2, but in fact, the K value is not a constant, but a variable that depends on other conditions such as thread accuracy. Under normal batch assembly conditions, the K value of the same joint can vary from 0.1 to 0.5 or more depending on the thread accuracy, material, surface condition, and lubrication condition, the higher the thread manufacturing precision, the more stable the surface treatment and lubrication conditions, the more stable the K value (small difference), on the contrary, the larger the difference.

When the difference in K value is taken into account, the upper and lower limits of the tightening torque of the bolt can be determined by the following formula in order to meet the design requirements of the pre-tightening force.

Mu=KLDFU

ML=KUDFL

Fu, FL-the upper and lower limits of axial preload required by design;

Ku, KL-the upper and lower limits of K value under specific process conditions;

The greater the difference in K value, the more strict the control of assembly torque (Mu-ML is smaller) after the design of thread connection (thread diameter d and axial force Fu, FL) is determined. Similarly, when the torque control accuracy (Mu, ML) is determined, the greater the difference in K value, the more the axial force is dispersed, and the worse the reliability of the thread connection is.

3. The relation between preload and corner

The fastener should be rotated in the process of tightening. What is the relationship between the preload and the angle of the fastener?

According to the kinematics of the thread and the analysis of the stress state of the fastener and the fastener, no preload is produced at the corner at the beginning of the screw bolt or nut, the pre-tightening force begins only when the end face of the connecting part touches the connected part, and only when it is fully fitted, F and θ have a linear relationship. The basic relationship between the pre-tightening force and the angle of rotation is as follows:

F=CPθ

(F-preload, C composite stiffness coefficient, p pitch, θ bolt head angle of turn) .

4. The relationship between torque and rotation angle ーー the incremental ratio of torque to rotation angle

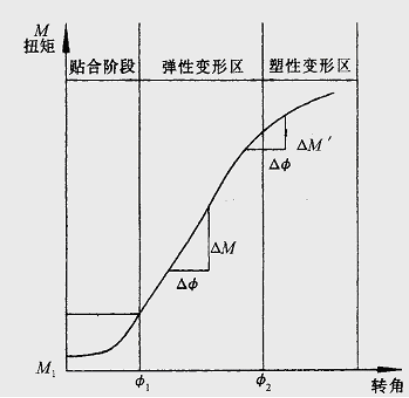

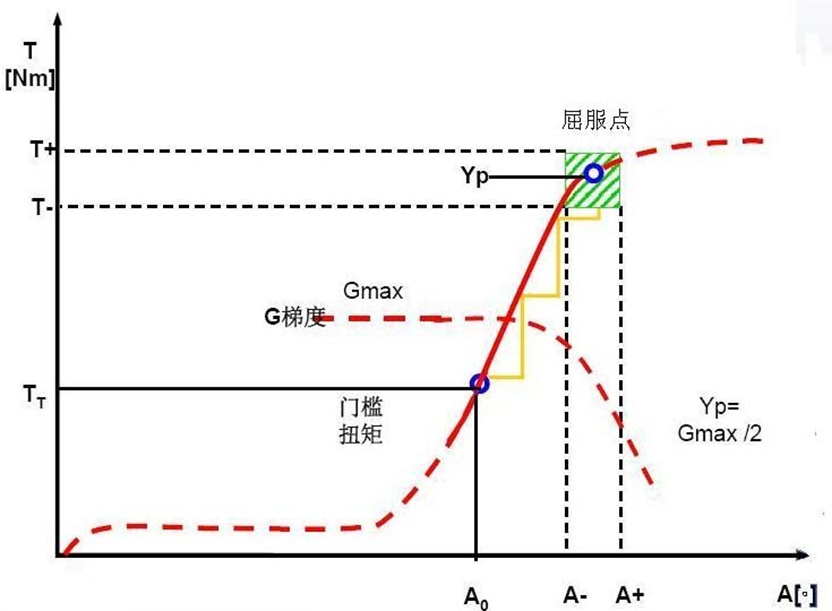

From the tightening process in the assembly process, when the bolt from the start of the screw into the joint surface starts contact, then as long as the accuracy of the thread qualified no knock, the screw torque is almost 0 or very small. Then it enters the fitting stage and begins to overcome part of the manufacturing error and the roughness of the contact surface, as well as the elastic deformation and plastic deformation of the clamped parts. There is a nonlinear relationship between the increase of torque and the change of rotation angle, and the increase of torque is very fast. Then it enters the stage of approximate elastic deformation, when the torque and the angle of rotation is a linear relationship, the increase of the angle of rotation represents the increase of deformation and is proportional to the change of preload. When the preload reaches the yield point of the bolt, the bolt begins to enter plastic deformation. At this point as long as a small torque increment, the bolt has a larger extension, so that the angle of the increment becomes very large. Therefore, the ratio of torque increment to angular increment is greatly reduced, which indicates that the yield point is reached. This process of change can be represented by the change curve shown in Figure 1.

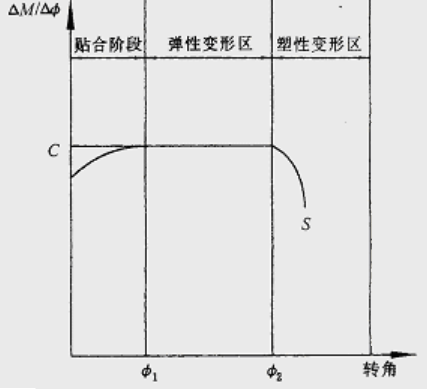

In Figure 1, the fitting torque M 1 is at the angle Φ1. From this point on, the torque increment is measured at a set interval of angular increments, and the δm/δφ value is calculated, as shown in Figure 2. When tightening to the angle Φ2, the yield point of the entry bolt, under the condition of the same angular increment δφ, the increment of the torque decreases greatly to δm, and when δm/δφ decreases to 1/2 ~ 1/3 of the value of C, the torque of the entry bolt will decrease to δm, the pre-tightening force of the bolt can be considered to reach the yield limit of the bolt and immediately stop the tightening process. The test shows that the total elongation of the bolt is 4 ~ 5 times of the elongation at the failure point, which means that there is a long plastic deformation stage. So there is still plenty of Factor of safety. Theoretical Research and practice have proved that bolt (especially high strength bolt) tightening to the yield strength limit, can maximize the potential of the bolt.

二、Several typical assembly torque control methods

Five typical assembly torque control methods are generally used in the assembly, they are direct torque control method, torque control-angle monitoring method, angle control-torque monitoring method, yield point control method, and bolt length method.

1、Direct torque control method (T)

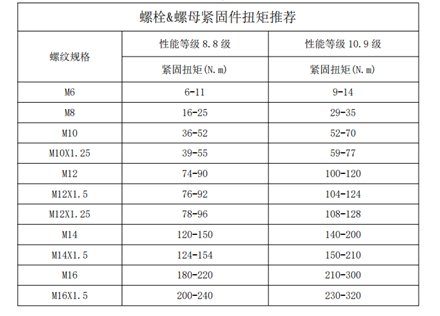

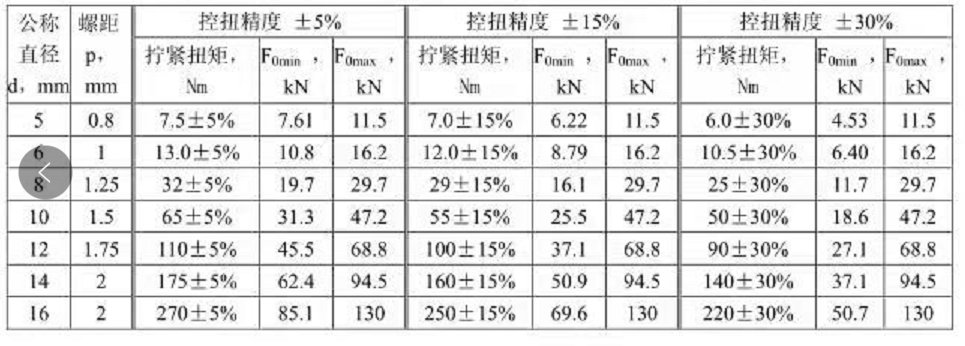

The direct torque control method is developed in the production according to the relationship between the torque m of the thread pair and the axial preload f of the bolt. The friction coefficient μs is the main factor that affects the assembly torque and the axial preload of the bolt. According to ISO standard, when the thread angle α = 60 °, it is approximately considered that the friction coefficient μn between the thread pair and the support surface of the thread is basically equal, that is, μs = μn. According to the calculation formula, according to the different friction coefficients and the different sizes of thread to calculate the assembly torque reference table, according to the following table to select the appropriate assembly torque.

The direct torque control method should not only consider torque control but also choose the tightening process reasonably. The commonly used tightening techniques include diagonal gradual tightening, group tightening, step tightening, multiple tightening, and some other special treatment methods.

Pros:

- Simple process and tools;

- Low cost;

Bolts can be reused.

Cons: - The axial preload fluctuates greatly;

- The utilization ratio of bolt tensile strength is low;

- The tightening result is greatly influenced by the friction coefficient of the bolt and the quality of the bolt.

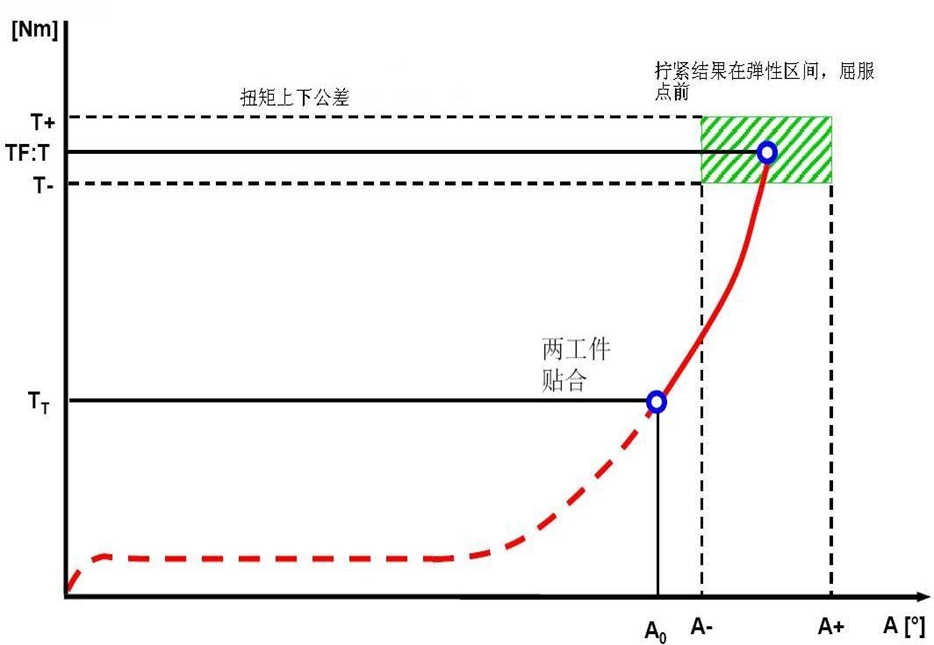

2、Torque control-angle monitoring method (TA)

The torque control-angle monitoring method generally uses automatic tightening machine control. The working procedure of the automatic tightening machine is as follows: firstly, the Assembly torque is set in the range of 70% ~ 80% of the final assembly torque. After the automatic tightening machine quickly tightens to this setting value, after a slight pause of 1 ~ 2 seconds, the tightening machine reduces the rotation speed, continues tightening at a very slow speed until the final assembly torque is reached. At the start of the second action, the angle of rotation is recorded so that the quality of the thread pair can be checked at the same time as the assembly is achieved. This method is basically the same as the first assembly method, except that the control precision is higher and the quality of bolts can be monitored by turning angle. If the corner is too large, it is clear that the thread-pair material used has too low tensile strength or has not been heat-treated; if the corner is too small, it is clear that the thread-pair material used has too high tensile strength or that the heat-treated material is too hard. Through the angle monitoring, can be very convenient to check out a number of bolt qualities, so as to maximize the assembly quality of screw pair materials.

Monitoring the size of the corner is generally obtained through experiments, through the calculation can also be obtained an approximate number, but the final results should be obtained through experiments. Because of the size of the rotation angle, it is actually the length of the bolt being stretched and the length of the connector being compressed. If the pitch of the bolt is 1 mm and the angle of rotation is 90 °, then obviously the total length of the bolt stretched and the length of the connector compressed is 0.25 mm.

The torque control-angle monitoring method is generally used in assembly parts with high assembly requirements, such as chassis bolts, gearbox and engine connection, transmission shaft connection, etc.

Pros:

- Accurately control the pre-tightening force;

- Making full use of the tensile strength of bolts;

- be able to detect faulty bolts.

Cons: - The tightening process is complex;

- The cost of tightening equipment is high;

- The friction coefficient has a great influence on the tightening

- Bolts are rarely reused.

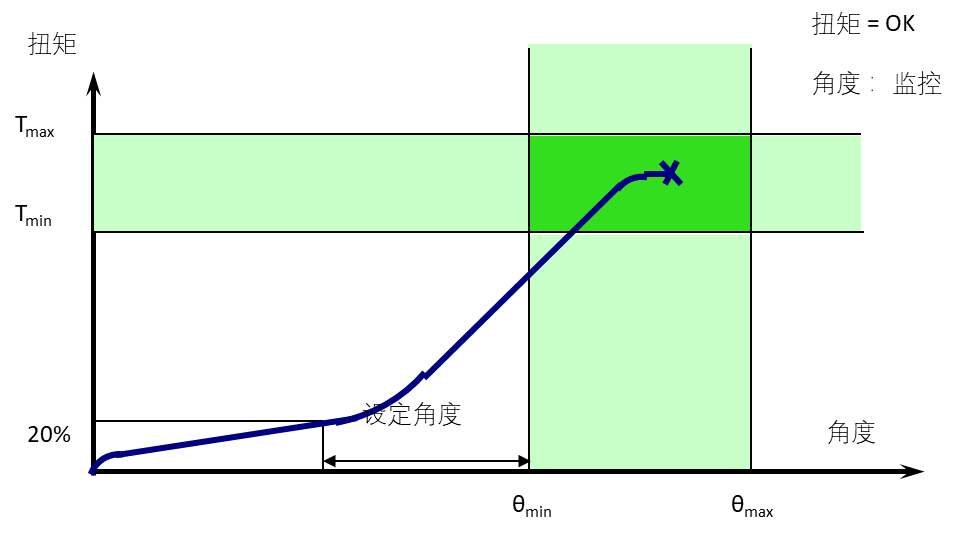

3、Angle control-torque monitoring method (AT)

The biggest disadvantage of torque control is that it is greatly affected by the friction coefficient, while the biggest advantage of angle control is that it is not affected by the friction coefficient, therefore, once the Angle Control is adopted, the axial preload of the bolt is almost not affected by the coefficient of friction and is only related to the total length of the bolt and the member compressed, i. e. the angle.

The angle control-torque monitoring method must first use the torque method to determine the starting point of Angle Control. This point is generally about 20% of the final assembly torque of the torque control method. After the automatic tightening machine quickly tightens to this point, after a slight pause of 1 to 2 seconds, the tightening machine changes the speed of rotation to slow it down, and then begins to rotate and start calculating the angle until you reach the required angle. This angle is usually about 90 degrees. While calculating the rotation angle, record the torque. If the torque is too big, obviously the bolt material is too high in tensile strength or too hard after heat treatment; if the torque is too small, obviously the bolt material is too low in tensile strength or poor heat treatment. Thus the assembly quality of thread pair material can be monitored.

The angle control-torque monitoring method is mainly used in important assembly parts, such as engine cylinder head bolt connection, connecting rod bolt, control arm connection, etc.

Pros:

- The axial preload is larger, and the relative dispersion is smaller, which can accurately control the axial elongation of bolts;

- It has better anti-fatigue performance, especially for sealing assembly with cushion

- The coefficient of friction has little effect on tightening

- be able to detect faulty bolts.

Cons: - The process is complex, and the control process parameters need to be determined by experiments

- The cost of tightening equipment is high, and the cost of maintenance is also high;

- Bolts are rarely reused.

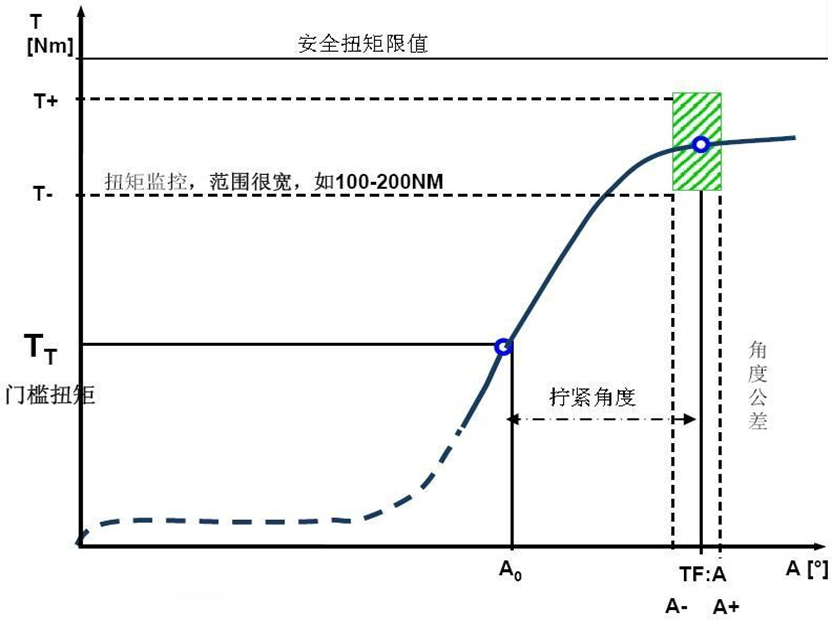

4、Yield Point control method (also known as slope control method or elastic limit method)

The yield point control method is to use the yield point of the thread material to control the assembly of the thread pair, the differential quotient δ between torque and rotation angle can be calculated by testing torque and rotation angle continuously, and the formula of the differential quotient is as follows: δm/δφ. When the material of the bolt reaches the yield point, that is, when the tightening moment no longer increases or increases very slowly, but the angle of rotation increases very quickly, it is equal to the differential quotient δ, which tends to be zero, it sends out a control signal, cut off the power supply, complete a work cycle, thus achieving the control of the assembly torque.

The bolt tightened by the yield point control method has high reliability, good anti-fatigue, and anti-looseness properties, and the yield point control method has higher requirements on the material and heat treatment of the bolt, so generally only for the axial preload or axial elongation requirements are particularly strict, and especially high-reliability requirements of the thread connection, such as the engine cylinder head bolt connection, connecting rod bolt.

Pros:

- It is not affected by the friction coefficient of the torque control method and the angle starting point of the Angle Control method, so the shortcomings of the torque control method and Angle Control method are overcome, and the assembly accuracy is improved

- The axial preloading force is large and concentrated, which can accurately control the axial elongation of the bolt and make full use of the tensile strength of the bolt

- The coefficient of friction has little effect on tightening

- be able to detect faulty bolts.

Cons: - The tightening process is complex, and the control process parameters need to be determined by the test

- The cost of tightening equipment is high, and the cost of maintenance is also high;

- Bolts can not be reused.

5、Bolt length method (also known as elongation control method)

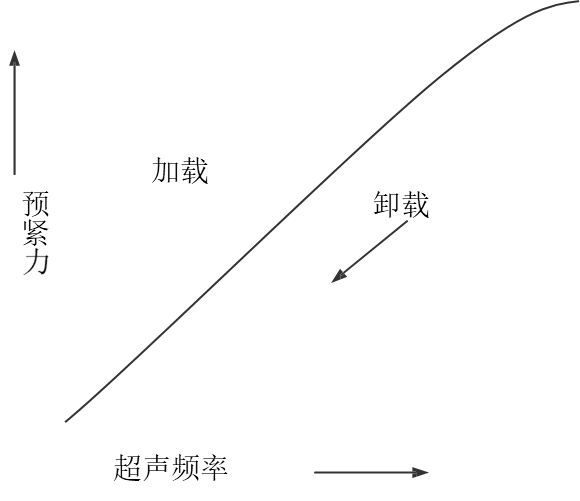

The method of bolt length is to measure the elongation of the bolt in the process of Assembly to control the assembly torque of the bolt, so as to directly control the axial preload of the bolt. It is the most accurate method to measure and control the pre-tightening force by measuring the bolt elongation directly with a micrometer or by measuring the bolt elongation (deformation) with a high-precision dynamic measuring instrument such as an ultrasonic length measuring instrument. This method can not only measure the axial force of the bolt at any time but also measure whether the bolt reaches the yield point.

The measuring principle formula is f = k * δl (f is the pre-tightening force, K is the stress factor of the bolt, the elongation of δl Bolt).

Pros:

The control precision of the pre-tightening force is high, and the pre-tightening force can be controlled within ± 5%

Cons:

These measuring methods and devices are very difficult in the continuous production process in terms of concrete structure and implementation methods, and can only be used in the laboratory, Product Design Research, process design stage, high requirements of aviation safety, can not be applied to a large number of production.