Q: What are the problems with the thread pass and stop gauge detection method?

A: The thread pass-and-stop gauge detection method has certain flaws. It cannot comprehensively evaluate key parameters such as the geometric error of the thread and the pitch diameter fit clearance, nor can it measure the true size of the thread.

In addition, the thread pass-and-stop gauge method has problems such as insufficient accuracy, low efficiency, and being greatly affected by wear.

When it comes to important threads, such as those in aerospace, nuclear power, and automobiles, it is not allowed only to use pass-and-stop gauges to evaluate quality.

For example, if there is an inverse taper error in the threads on nuclear power bolts, the pass-and-stop gauge will still judge it as qualified, but the connection strength cannot be guaranteed, and fracture failure will easily occur after loading.

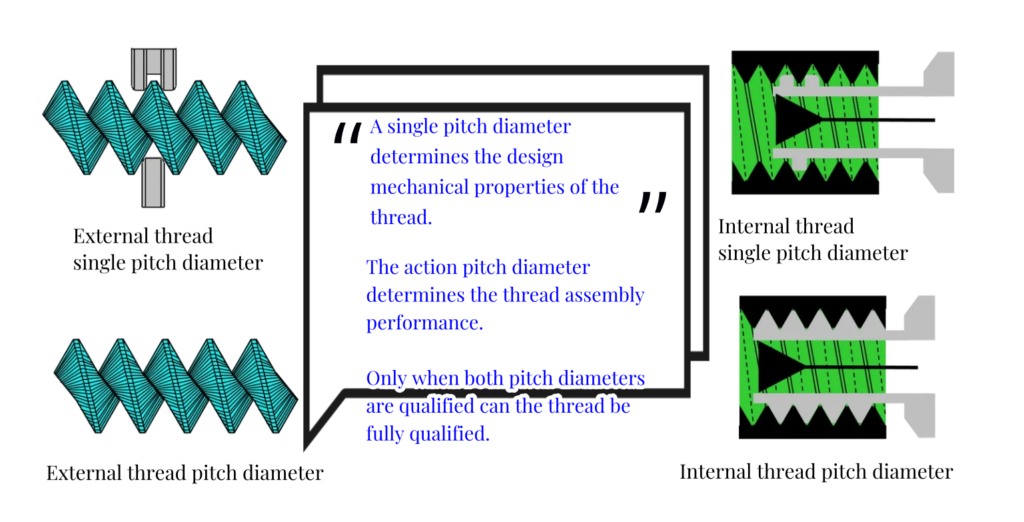

Q: What is the reason why the “pass-stop gauge” method cannot control the pitch-diameter fit clearance?

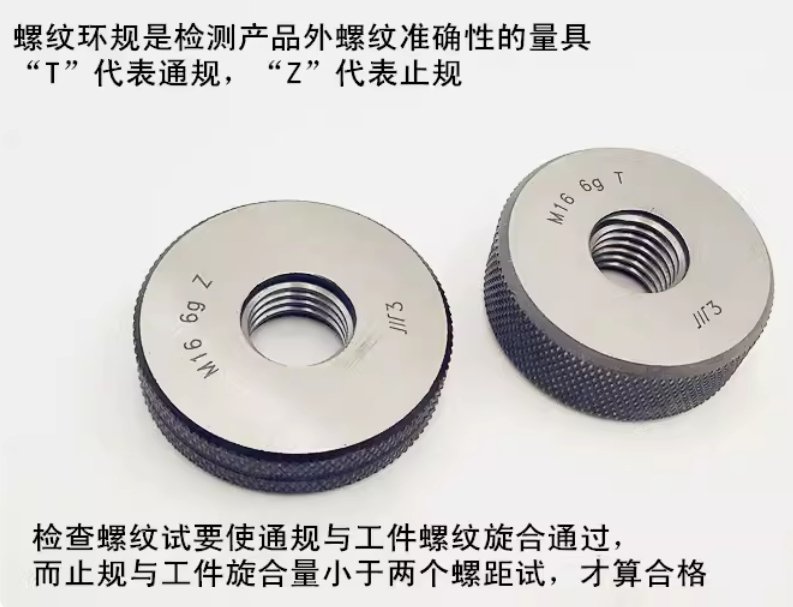

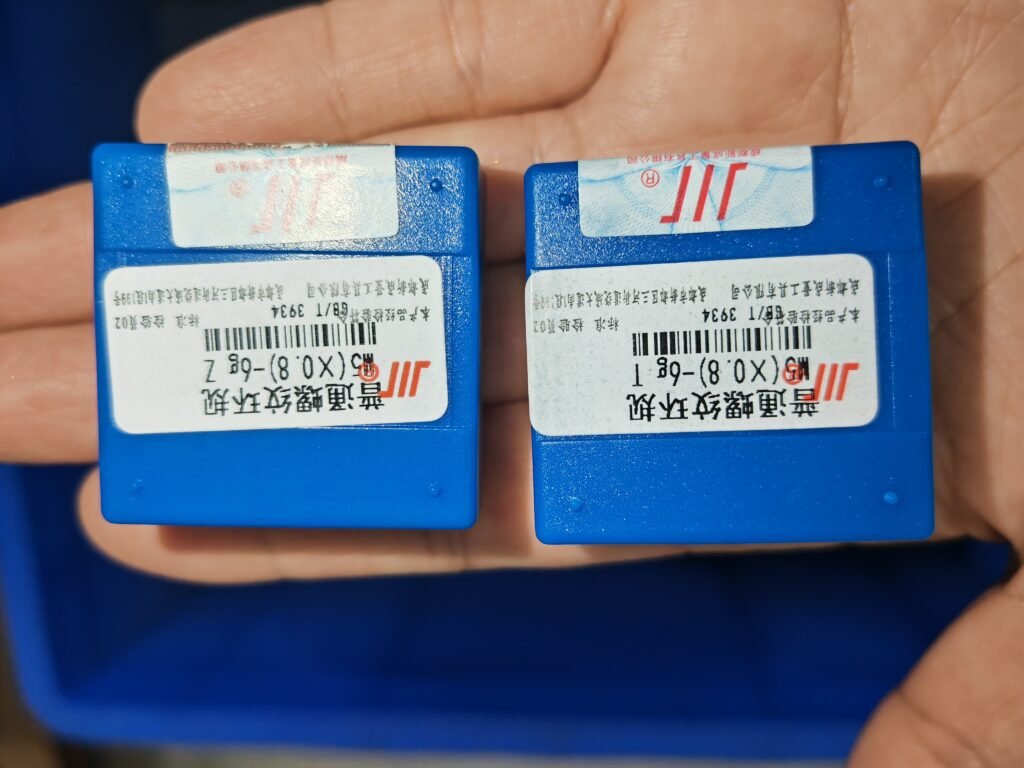

A: The pass-and-stop gauge is a tool used to check whether threaded fasteners meet assembly requirements.

There are two main reasons:

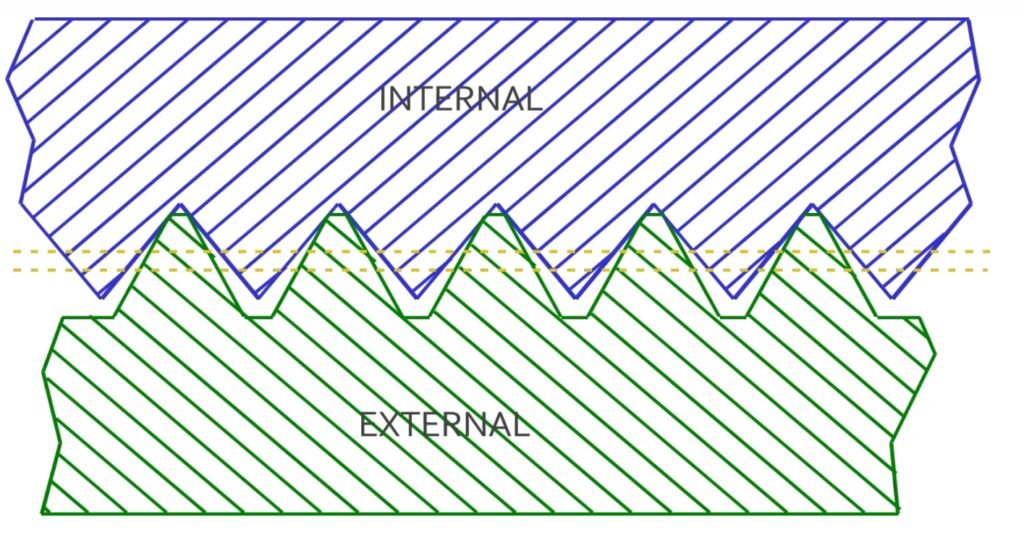

First, the pass-and-stop gauge can only provide qualitative dimensional information and cannot fully reflect the true shape and dimensional error of the thread;

Secondly, the prescriptive measurement results cannot analyze the size of the middle diameter fitting gap, so the strength and stability of the threaded connection cannot be accurately evaluated.

This is why in some fields with high requirements for threaded connections, such as aerospace, nuclear power and automobiles, the go-no-go gauge method is considered inaccurate enough, and more scientific and accurate measurement methods need to be adopted, such as thread indicator gauges.

Q: Why is it said that the “pass-and-stop gauge” cannot fully guarantee thread quality?

For example, if the thread has an inverted taper shape, the internal thread has a drum shape, the external thread has a concave shape, the thread has an out-of-tolerance roundness, an out-of-tolerance flank angle, an out-of-tolerance pitch error, etc., all of them may be qualified if detected with a go-no-go gauge. threads, but they are substandard threads.

Only when there is no shape error in the thread, the pass-stop gauge is an effective measurement method. But in most cases, thread shape errors cannot be ignored.

Dongguan Hongzhuo Hardware Products Co., Ltd, will become more and more professional fasteners supplier. Welcome to contact us for any inquiry.