Benefits of Using Stainless Steel Clinch Studs

Stainless steel clinch studs are a game-changer in fastening technology. They offer unmatched durability and reliability. These studs are perfect for various applications, from construction to electronics.

Their high corrosion resistance makes them ideal for harsh environments. This includes outdoor and marine settings. Stainless steel clinch studs ensure long-lasting performance.

Installation is straightforward, often requiring no special tools. This saves time and reduces labor costs. The result is a clean, professional finish.

These studs are versatile, fitting both thin and thick materials. They enhance structural integrity and aesthetic appeal. Their use is widespread in industries like automotive and aerospace.

Choosing stainless steel clinch studs is a smart investment. They offer a cost-effective, eco-friendly solution. Their benefits make them a preferred choice for professionals.

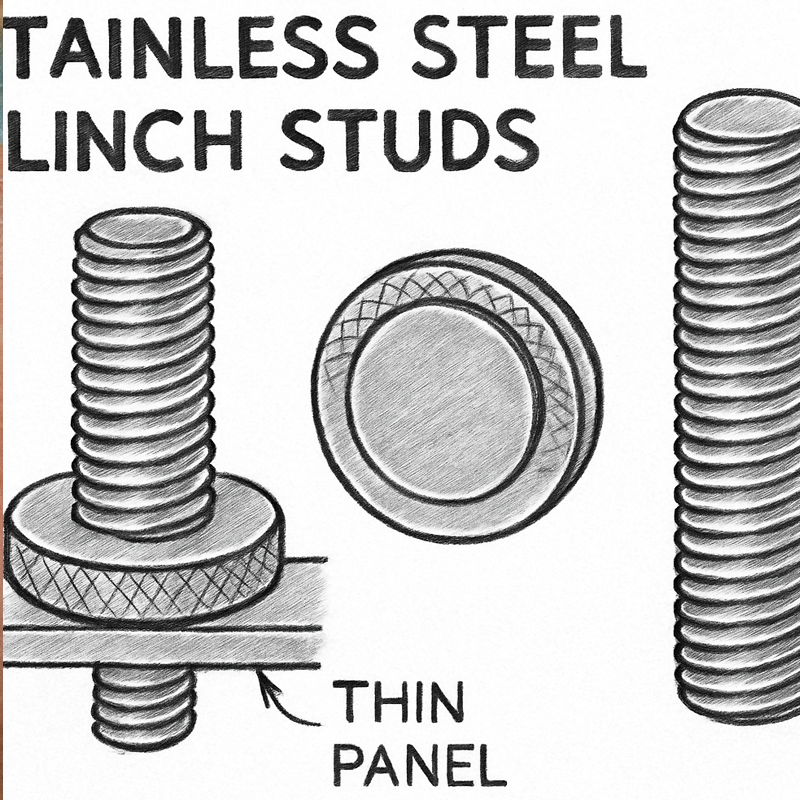

What Are Stainless Steel Clinch Studs?

Stainless steel clinch studs are specialized fasteners. They are designed to securely attach various materials. These studs offer a permanent and sturdy solution.

Typically, a clinch stud is pressed into a pre-punched hole. The material around the hole deforms to grip the stud tightly. This creates a robust, integrated attachment.

Here are key features of stainless steel clinch studs:

- Material: Stainless steel for corrosion resistance

- Design: Flush installation for a smooth surface

- Durability: Long-lasting even in tough environments

Stainless steel clinch studs are widely used in many industries. They include aerospace, automotive, and electronics. Each sector benefits from their strength and reliability.

Key Advantages of Stainless Steel Clinch Studs

Stainless steel clinch studs offer many benefits. First, their corrosion resistance stands out. This makes them perfect for outdoor and marine use.

These studs provide strength you can depend on. They ensure a secure fastening, minimizing the need for frequent replacements. This reliability is crucial in critical applications.

Furthermore, installation is simple and quick. You often do not need special tools. This ease reduces labor costs and time spent on the job.

Here’s a list of advantages offered by stainless steel clinch studs:

- Corrosion Resistance: Ideal for harsh environments

- Strength and Durability: Suitable for heavy loads

- Easy Installation: Saves time and resources

- Versatile: Used in various materials

- Aesthetic Finish: Clean look

Stainless steel’s non-reactive nature makes these studs suitable for sensitive settings. They are perfect for electronics and food processing sectors.

The aesthetic benefits are worth mentioning. Clinch studs sit flush with surfaces, offering a neat, professional look. This improves the visual appeal of any assembly.

Comparison: Stainless Steel vs. Other Metal Studs

Choosing the right metal stud for your project is vital. Stainless steel clinch studs have distinct benefits over other metal studs. This comparison will highlight the key differences.

Stainless steel offers superior corrosion resistance. This makes it a better choice for outdoor applications compared to plain steel or aluminum studs. The durability of stainless steel ensures longevity, which other metals may not provide.

In contrast, some other metal studs may be lighter or less costly initially. However, they may require more frequent replacements due to wear and tear. Stainless steel’s strength means it can handle heavy-duty applications without distortion.

Here’s a quick comparison between stainless steel and other metal studs:

- Corrosion Resistance: Stainless steel wins

- Strength: Stainless excels in heavy loads

- Weight: Other metals may be lighter

- Cost: Non-stainless options may be cheaper upfront

- Longevity: Stainless steel requires less maintenance

In conclusion, while other metals may suit budget constraints, stainless steel clinch studs offer long-term value and reliability unmatched by most alternatives.

Common Applications of Stainless Steel Clinch Studs

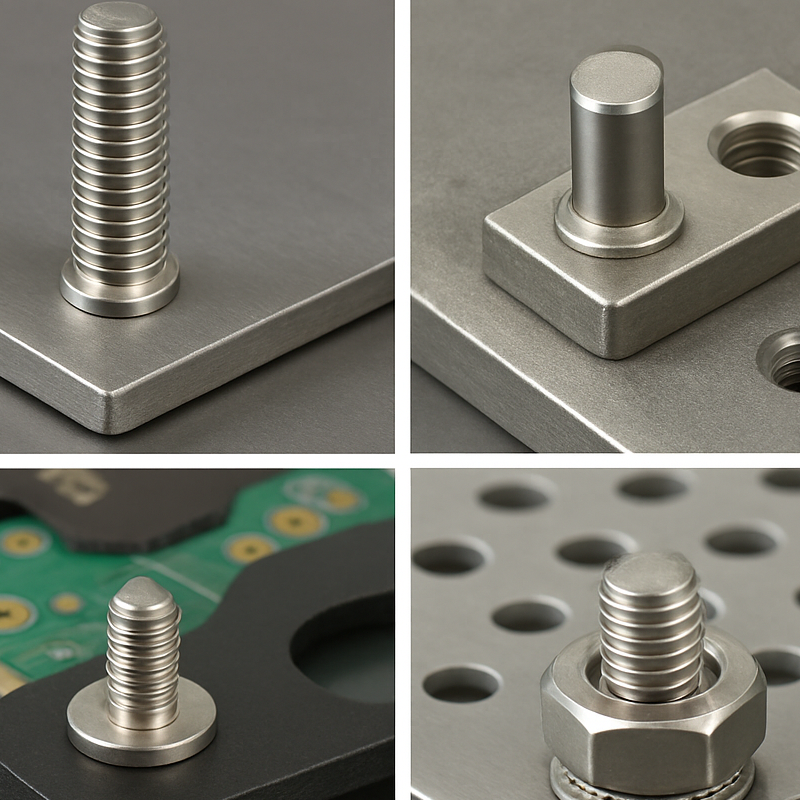

Stainless steel clinch studs are versatile fasteners used across many sectors. Their strength and durability make them an ideal choice in demanding environments. Let’s explore some of their common applications.

These studs are widely used in the automotive industry for securing panels and components. Their corrosion resistance is particularly beneficial in vehicles exposed to the elements. In aerospace, their lightweight yet strong nature helps reduce overall aircraft weight.

In the electronics industry, stainless steel clinch studs provide reliable mounting for components. Their excellent electrical conductivity is crucial in these applications. Additionally, they are invaluable in food processing due to their hygiene properties.

Here are some industries where they are frequently used:

- Automotive

- Aerospace

- Electronics

- Food processing

- Medical equipment

Stainless steel clinch studs are the go-to choice for many professionals. Their diverse applications ensure they meet the needs of various industries efficiently.

Installation Process and Best Practices

Installing stainless steel clinch studs is a straightforward process. Their design ensures easy integration into materials without causing surface damage. This simplicity makes them a popular choice among engineers and DIY enthusiasts alike.

Firstly, ensure the substrate material is prepared correctly. A punched or drilled hole is typically required. Once the hole is ready, the clinch stud is inserted and pressure is applied to fix it in place. It’s essential that the force used is appropriate to avoid distorting the stud or material.

For optimal results, follow these best practices:

- Use the correct size hole for the stud.

- Ensure material thickness matches stud specifications.

- Apply consistent pressure during installation.

Adhering to these guidelines ensures a secure fit and extends the stud’s lifespan. Proper installation maximizes the benefits of these durable fasteners.

Environmental and Economic Benefits

Stainless steel clinch studs offer impressive environmental advantages. Made from recyclable materials, these studs promote sustainability in manufacturing. Their durability reduces the need for frequent replacements, thus minimizing waste.

Economically, stainless steel clinch studs provide long-term cost savings. Their robustness lowers maintenance expenses, making them a cost-effective solution for extensive projects. Over time, the initial investment is offset by reduced repair and replacement costs.

Key benefits include:

- High recyclability of stainless steel.

- Long-lasting, reducing waste and maintenance.

- Cost-effective over the life of a project.

These benefits make stainless steel clinch studs a smart choice for eco-conscious and budget-sensitive applications alike.

Conclusion: Why Choose Stainless Steel Clinch Studs?

Stainless steel clinch studs offer remarkable durability and resistance, making them ideal for diverse applications. Their ability to withstand harsh environments and maintain strength makes them reliable.

By choosing stainless steel clinch studs, you invest in quality and longevity. Their numerous benefits, like easy installation and environmental friendliness, make them a preferred option for professionals and hobbyists alike. Ultimately, these studs deliver unmatched performance and value for any project.