Benefits of Using Self Clinching Stud Press

In the world of manufacturing, precision and efficiency are key. Fastening solutions play a crucial role in achieving these goals. One such solution is the self clinching stud press.

This tool is essential for installing self clinching studs. It offers a reliable and efficient method for fastening in various applications.

Self clinching studs provide strong, permanent threads in thin sheet metal. They are ideal for situations where space is limited and a flush finish is needed.

The self clinching stud press eliminates the need for welding. This reduces the risk of heat distortion and material damage.

Industries like automotive, aerospace, and electronics benefit from this technology. It ensures consistent and reliable fastening, improving product quality.

Understanding the benefits of a self clinching stud press can enhance your manufacturing process. It offers a cost-effective and durable fastening solution.

What Is a Self Clinching Stud Press?

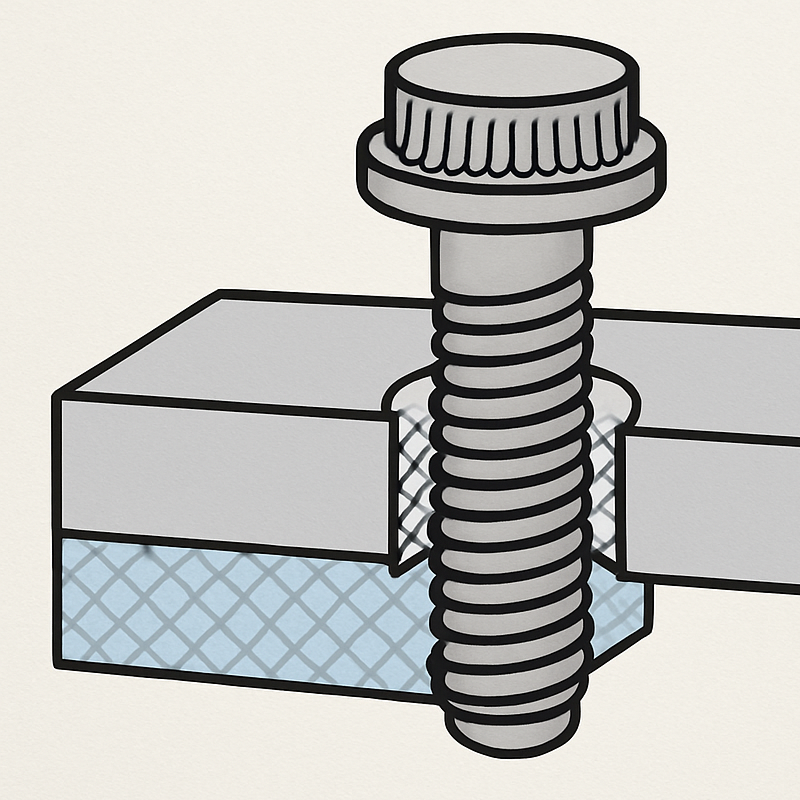

A self clinching stud press is a specialized tool for installing self clinching studs into metal sheets. It uses pressure to secure the studs in place, ensuring a strong and permanent bond.

The press utilizes a precise mechanism to embed the stud into a pre-punched hole. This process displaces the surrounding material, creating a tight and secure fit.

Various types of presses are available, tailored to different production needs:

- Manual Presses: Ideal for smaller operations with lower volume.

- Pneumatic Presses: Suitable for moderate production demands.

- Hydraulic Presses: Designed for high-volume environments.

Each type offers unique benefits, such as speed, ease of use, and adaptability. These presses ensure that the installation is consistent, reducing the likelihood of misalignment. With the right press, businesses can achieve high efficiency and reliability in their fastening tasks. The versatility of a self clinching stud press makes it a valuable tool in many industries.

How Self Clinching Studs Work: The Technology Explained

Self clinching studs offer a compelling solution for fastening in thin metal sheets. They are designed to create strong threads within the sheet metal itself. This mechanism eliminates the need for additional anchors or supports, simplifying the assembly process.

The installation process involves pressing the stud through a pre-punched hole. During this, the stud displaces the surrounding material and forms a secure anchor. This results in a robust and reliable connection that withstands significant force.

Key features that highlight this technology include:

- High Torque-Out Resistance: Prevents the stud from turning.

- High Push-Out Resistance: Keeps the stud firmly in place.

- Flush Finish: Provides a clean and smooth surface appearance.

This technology ensures efficiency and precision in fastening applications. The reliability of self clinching studs makes them ideal for diverse industrial uses, from electronics to automotive sectors.

Key Benefits of Using a Self Clinching Stud Press

Using a self clinching stud press offers several noteworthy benefits for various applications. This method stands out in the world of fastening solutions by providing accuracy and efficiency.

One major advantage is the reduction in assembly time. Press installation is faster than welding or using traditional fasteners. This means less time spent on assembly, leading to increased productivity.

Another significant benefit is cost-effectiveness. The process requires less labor and fewer resources, which lowers overall production costs. This saving makes self clinching stud presses an attractive option for high-volume manufacturing.

Additionally, the installation is consistent and reliable. The press ensures each stud is perfectly aligned and secured. This consistency improves the quality of the final product and reduces errors.

Self clinching stud presses also enhance structural integrity. The studs provide strong, permanent threads within thin materials, which improves durability and longevity. This strength is vital in critical applications, such as aerospace and automotive.

Key benefits include:

- Efficiency: Speeds up the assembly process.

- Cost Savings: Reduces labor and material costs.

- Quality: Ensures precise and reliable fastening.

Moreover, the aesthetic finish is a compelling reason for choosing this method. The press creates a flush, clean surface, enhancing the product’s appearance. This is crucial for consumer-facing products where looks matter.

Additional advantages:

- Durability: Withstands vibrations and shocks.

- Versatility: Suitable for various materials and thicknesses.

- Sustainability: Environmentally friendly with minimal waste.

Finally, safety is a key consideration. The self clinching stud press minimizes the need for manual handling and risky welding operations. Enhanced safety measures protect workers and ensure a safer work environment.

Comparison: Self Clinching Studs vs. Other Fastening Solutions

When it comes to fastening solutions, self clinching studs offer several distinct advantages over traditional methods. They are ideal for thin sheet metals where other fasteners fall short.

In contrast, welding or screwing often requires more material and time, increasing production costs. Self clinching studs eliminate the need for additional fasteners, simplifying assembly. The lack of heat application in pressing reduces the risk of thermal damage, unlike welding.

Traditional fasteners sometimes compromise the material’s structural integrity. However, self clinching studs create strong, permanent connections without weakening the material. This provides a reliable and long-lasting solution.

Comparing key aspects:

- Material Integrity: Self clinching studs do not require heat or holes.

- Efficiency: Faster and more straightforward than welding or adhesive.

- Aesthetic: Offers a flush, clean surface finish.

Overall, while other methods have their place, self clinching studs provide a more efficient and aesthetically pleasing solution. They cater to industries where precision and appearance are crucial. This makes them an essential choice in modern manufacturing environments.

Applications Across Industries

Self clinching studs find widespread use across various industries due to their unique advantages. In the automotive sector, they are employed to join thin sheet metals securely. This eliminates the need for welding, thus protecting delicate parts from heat damage.

The aerospace industry appreciates the weight savings self clinching studs offer. This is crucial in aircraft manufacturing where every gram matters for fuel efficiency. Their high torque resistance ensures safety and durability under extreme conditions.

In electronics, self clinching studs provide excellent electrical conductivity. They maintain circuit integrity while supporting structural components. This makes them indispensable in assembling sensitive electronic products.

Key industry applications:

- Automotive: Enhanced vehicle structure.

- Aerospace: Lightweight durability.

- Electronics: Reliable electrical connections.

The versatility and reliability of self clinching studs extend to telecommunications and even consumer products. Their ability to handle dynamic loads makes them a preferred choice in demanding environments.

Types of Self Clinching Studs and Presses

Self clinching studs come in various materials and forms, catering to diverse industrial needs. They are commonly made from stainless steel, aluminum, and zinc-plated steel. The choice depends on specific application demands such as strength, conductivity, or resistance to corrosion.

Presses used for installation also vary. Depending on production scale and precision requirements, they can be manual, pneumatic, or hydraulic. Each type of press offers specific advantages in terms of power, speed, and ease of use.

Common types of self clinching studs and presses:

- Material: Stainless steel, aluminum, zinc-plated

- Press Types: Manual, pneumatic, hydraulic

By understanding these variations, businesses can select the right studs and presses to optimize their assembly processes. This ensures both efficiency and high-quality results, regardless of industry-specific challenges.

Installation Process: Step-by-Step Guide

Installing self clinching studs involves a straightforward but precise process. Proper execution is critical for ensuring strong and reliable fastening. Here is a step-by-step guide to help you achieve optimal results.

First, prepare the sheet metal by drilling a pre-punched hole. The hole must meet the size and tolerance requirements specified by the stud manufacturer. This ensures a secure fit and prevents material damage during installation.

Position the self clinching stud over the hole. Ensure it aligns perfectly to avoid any misplacement. Misalignment can lead to weak fastening and potential failure in high-stress applications.

Quick Steps for Installing Self Clinching Studs:

- Drill: Prepare the pre-punched hole.

- Align: Place the stud correctly over the hole.

- Press: Use the right press tool to insert the stud.

- Secure: Check for a flush and firm fit.

Finally, use the self clinching stud press to insert the stud into the hole. Apply consistent pressure until the stud displaces the surrounding material, creating a secure hold. After installation, inspect the connection to ensure the stud sits flush with the sheet, guaranteeing a smooth finish and strong fastening.

Tips for Selecting the Right Self Clinching Stud Press

Choosing the right self clinching stud press is crucial for optimal performance. Consider the specific requirements of your production environment before making a decision. Each press type offers distinct advantages that should align with your needs.

Important Factors to Consider:

- Production Volume: Match the press type to the scale of your production.

- Material Compatibility: Ensure the press supports various materials.

- Automation Level: Decide between manual, pneumatic, or hydraulic options.

- Customizability: Check for adjustable settings to handle different stud sizes.

By considering these factors, you can select a press that enhances efficiency, reduces costs, and ensures high-quality results.

Maintenance and Safety Considerations

Proper maintenance of your self clinching stud press ensures longevity and performance. Regular checks prevent unexpected breakdowns and maintain efficiency. Prioritize routine inspections and cleaning to keep it in optimal condition.

Key Maintenance and Safety Tips:

- Regular Inspections: Monitor for wear and tear.

- Lubrication: Keep moving parts well-lubricated.

- Operator Training: Ensure operators are skilled.

- Safety Features: Utilize built-in safety mechanisms.

By adhering to maintenance schedules and promoting safety practices, you extend the life of your equipment. This proactive approach protects both the machinery and your workforce.

Conclusion: Why Choose Self Clinching Stud Press for Your Fastening Needs?

Opting for a self clinching stud press provides numerous advantages in fastening applications. It offers a secure and reliable method, enhancing the quality of your products.

This technology not only streamlines operations but also reduces costs and improves aesthetics. Its versatility across various industries makes it a preferred choice for professionals seeking efficient and effective fastening solutions. Embrace the benefits of self clinching studs to stay competitive and ensure the durability of your assemblies.