Benefits of Self Clinching Stud Installation Techniques

In today’s fast-paced manufacturing environment, efficiency and reliability are paramount. To meet these demands, manufacturers continually seek innovative techniques and tools that streamline operations without compromising on quality. One way to achieve these goals is through the use of self clinching stud installation techniques. These techniques offer a variety of benefits that make them an essential component in numerous industries, from electronics to automotive manufacturing. Their ease of use and robust performance contribute significantly to advancements in production processes, helping industries meet the increasing demands for faster and more reliable manufacturing solutions.

As industries evolve, the need for components that provide both strength and simplicity becomes more crucial. Self clinching studs fulfill this requirement by offering a seamless integration into existing manufacturing setups. They not only enhance the structural integrity of products but also improve the efficiency of production lines. This article delves into the various benefits of self clinching stud installation techniques, shedding light on why they are becoming indispensable in modern manufacturing.

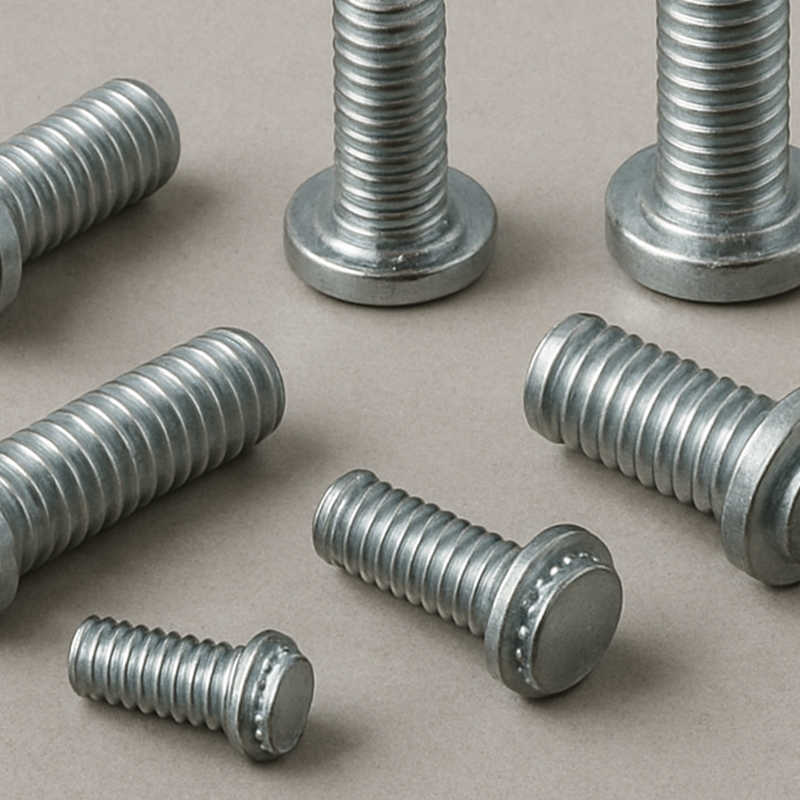

Self clinching studs are fasteners that are pressed into a material, usually sheet metal, to provide a secure and permanent thread for further attachment. Unlike traditional fasteners, which may require additional hardware or welding, self clinching studs are designed to become an integral part of the material into which they are installed. This unique characteristic allows them to offer a level of permanence and stability that is hard to achieve with other fastening methods.

Furthermore, their integration into the material means that they do not rely on external components to maintain their hold. This intrinsic connection minimizes the risk of loosening over time, providing a solution that is both reliable and durable. The self clinching nature of these studs also simplifies the assembly process, reducing the need for specialized tools or equipment. As a result, they are a preferred choice in applications where efficiency and reliability are critical.

How Do They Work?

The process involves placing the stud into a pre-drilled hole and applying pressure, which causes the material to flow into a specially designed recess in the stud. This creates a strong and durable connection that resists torque and vibration. The precision design of the stud ensures that it locks into place securely, maintaining its position even under significant stress.

The mechanics behind this process are rooted in material deformation, where the host material conforms around the stud, forming a bond that is nearly as strong as the material itself. This method not only enhances the joint’s strength but also distributes stress more evenly across the surface, reducing the likelihood of material fatigue. As a result, self clinching studs are particularly effective in high-stress environments where stability and endurance are paramount.

Advantages of Self Clinching Stud Installation

Enhanced Durability

One of the primary advantages of self clinching studs is their enhanced durability. Because they become part of the material, they are less likely to loosen over time compared to traditional screws or bolts. This makes them ideal for applications where long-term reliability is crucial. The permanent nature of the installation means that they can withstand repeated stress cycles without degradation.

Additionally, their resistance to vibration and torque further contributes to their longevity. In environments where mechanical components are subjected to constant movement or pressure, self clinching studs maintain their integrity, reducing the need for frequent maintenance or replacement. This durability not only saves time and resources but also ensures the safety and reliability of the final product.

Time Efficiency

The installation process for self clinching studs is quick and straightforward. With no need for additional hardware or adhesives, they can be installed rapidly, saving valuable time in the manufacturing process. This efficiency can lead to significant cost savings, particularly in large-scale production environments. The simplicity of the installation also reduces the potential for errors, ensuring consistent quality across all units.

Moreover, the reduction in setup time and equipment changes enhances overall production flow. Manufacturers can achieve faster turnaround times, meeting customer demands more effectively while maintaining high standards of quality. This streamlined process is especially beneficial in industries where time-to-market is a critical factor in maintaining competitive advantage.

Improved Aesthetics

Self clinching studs provide a clean and professional appearance. Since they do not protrude from the surface, they maintain the aesthetic integrity of the product. This is especially important in industries like consumer electronics, where appearance can be as crucial as functionality. The flush finish achieved with self clinching studs contributes to sleek, modern designs that appeal to consumers.

Furthermore, the elimination of external fasteners enhances the overall design flexibility. Designers can focus on creating products that are not only functional but also visually appealing, without the constraints imposed by visible fasteners. This aesthetic advantage is a significant consideration in markets where design plays a critical role in consumer decision-making.

Weight Reduction

In applications where weight is a concern, such as in the aerospace or automotive industries, self clinching studs offer a significant advantage. By eliminating the need for additional fasteners or adhesives, they contribute to overall weight reduction, enhancing performance and efficiency. This weight saving is crucial in industries where every gram counts, leading to improved fuel efficiency and reduced operational costs.

Additionally, the use of lighter materials without sacrificing strength allows for more innovative design possibilities. Engineers can explore new configurations and structures, pushing the boundaries of what is achievable in terms of performance and sustainability. The ability to reduce weight without compromising on durability is a key benefit that positions self clinching studs as a preferred choice in weight-sensitive applications.

Applications of Self Clinching Studs

Electronics Industry

In the electronics industry, self clinching studs are often used to mount circuit boards and other components securely. Their ability to provide strong, reliable connections without adding bulk makes them ideal for the compact designs of modern electronics. The minimal space requirement of these studs allows for more complex and densely packed assemblies, maximizing functionality within a limited footprint.

Furthermore, their durability ensures that electronic components remain securely attached, even in devices that experience frequent handling or movement. This reliability is essential for maintaining the performance and longevity of electronic products, reinforcing their reputation for quality in a competitive market.

Automotive Industry

Automotive manufacturers frequently use self clinching studs for assembling parts such as dashboards and body panels. The vibration resistance and durability of these fasteners ensure that components remain securely attached, even under the stresses of driving. This reliability is crucial in ensuring the safety and performance of vehicles, particularly in high-performance or off-road applications.

In addition to their mechanical benefits, self clinching studs contribute to streamlined manufacturing processes in the automotive industry. Their ease of installation reduces assembly time, allowing manufacturers to produce vehicles more efficiently while maintaining high standards of quality and safety. This efficiency is vital in a sector where production timelines and costs are constantly scrutinized.

Aerospace Industry

In aerospace applications, every ounce of weight matters. Self clinching studs are used to attach lightweight panels and components, contributing to the overall efficiency of the aircraft without compromising on strength or reliability. The ability to secure components firmly while minimizing weight is a significant advantage in an industry where fuel efficiency and payload capacity are critical.

Moreover, the robust nature of self clinching studs ensures that they can withstand the extreme conditions encountered in aerospace environments, from high vibrations to temperature fluctuations. This reliability is essential for maintaining the structural integrity and safety of aircraft, underpinning their widespread use in the aerospace sector.

Installation Techniques

Press Installation

The most common method of installing self clinching studs is through a press. This technique involves using a press machine to apply consistent pressure, embedding the stud into the material. It’s a highly effective method that ensures proper alignment and a secure fit. The precision of press installation provides confidence in the consistency and quality of the fastening process, critical for mass production.

Press installation also allows for rapid and repetitive application, making it ideal for high-volume manufacturing. The automation potential of this method further enhances its appeal, as it can be easily integrated into existing production lines, maximizing efficiency and minimizing labor costs.

Manual Installation

For smaller projects or repairs, manual installation can be done using a simple hand tool. While not as fast as press installation, it still provides a reliable connection when done correctly. This method offers flexibility for custom or low-volume projects where the use of complex machinery might not be justified.

Manual installation also provides the advantage of being more accessible in remote or constrained environments where large machinery cannot be deployed. This adaptability ensures that self clinching studs can be used in a wide range of applications, regardless of scale or locati0n.

Automated Installation

In large-scale manufacturing, automated systems can be employed to install self clinching studs quickly and efficiently. These systems integrate with production lines, ensuring consistent quality and reducing labor costs. Automation not only speeds up the installation process but also enhances precision, leading to fewer defects and rework.

The integration of automated installation techniques aligns with the broader trend of Industry 4.0, where smart manufacturing processes are being adopted to improve productivity and quality. By leveraging automated systems, manufacturers can achieve higher throughput and better utilization of resources, further enhancing the overall benefits of self clinching stud installations.

Considerations for Using Self Clinching Studs

Material Compatibility

When selecting self clinching studs, it’s essential to consider the compatibility with the material they will be installed in. Most studs are designed for use with sheet metal, but there are options available for other materials like plastics and composites. Understanding the material properties and choosing the right stud ensures optimal performance and longevity of the connection.

Additionally, the thickness and hardness of the material are critical factors that influence the effectiveness of the installation. Proper assessment and selection can prevent issues such as deformation or inadequate bonding, safeguarding the integrity of the assembly.

Load Requirements

The strength of the connection is another critical factor. Ensure that the selected stud can handle the expected load and stress of the application to prevent failures. Considering the dynamic forces that the connection will be subjected to helps in selecting the appropriate stud size and type, ensuring reliability under operational conditions.

Furthermore, understanding the load distribution and stress points within the assembly can inform the placement and number of studs required. This strategic planning minimizes the risk of overloading any single connection point, contributing to the overall robustness of the structure.

Environmental Factors

Consider the environment in which the studs will be used. For example, if they will be exposed to corrosive elements or extreme temperatures, choose studs made from materials that can withstand those conditions. Material selection based on environmental exposure ensures that the studs maintain their structural integrity and appearance over time.

In addition to material considerations, protective coatings or treatments may be applied to enhance resistance to environmental factors. These precautions extend the lifespan of the fasteners and preserve the functionality and aesthetics of the final product, ensuring customer satisfaction and reducing maintenance costs.

Conclusion

Self clinching stud installation techniques offer numerous benefits that make them an attractive choice for manufacturers across various industries. Their durability, efficiency, and aesthetic appeal make them an invaluable tool in the quest for reliable and cost-effective manufacturing solutions. By understanding the applications and proper installation methods, businesses can leverage these advantages to improve their products and processes.

Whether you’re in electronics, automotive, aerospace, or another industry, self clinching studs can provide the secure, reliable connections you need. As technology advances and demands for efficiency and sustainability grow, these fasteners will likely become even more integral to modern manufacturing practices. Embracing these techniques not only enhances current operations but also positions companies to meet future challenges with confidence and innovation.