Self-clinching fasteners, the utility model is a powerful fastener, which can be directly screwed into a thin metal plate without pre-processing thread holes, and provides a convenient and efficient connection scheme for users. With its unique fastening principle and extensive application advantages, Self-clinching fasteners have been widely used in sheet metal, electronics, automotive, aerospace, and other fields.

1. Advantages: self-clinching fasteners charm

Self-clinching fasteners have the following significant advantages over conventional fasteners:

Simple and efficient: no need to prefabricate thread hole, directly screw in, significantly improve assembly efficiency.

Firm and reliable: the unique fastening principle ensures the connection is firm and reliable, and anti-vibration, and tensile performance is excellent.

Cost saving: the step of processing the threaded hole is exempted, and the production cost is reduced.

Widely used: can be used for all kinds of thin metal plate connections, such as aluminum plate, steel plate, and stainless steel plate.

2. Variety of applications: meet different needs

Self-tightening screws are widely used in various fields because of their unique advantages:

Sheet metal parts connection: for connecting the air conditioning shell, chassis cabinet, and other sheet metal parts.

Installation of electronic equipment: used for fixing circuit boards, electronic components, etc.

Auto parts fixing: Used for fixing auto door panels, bumpers, and other parts.

Aerospace equipment: for connecting aircraft skin, spacecraft shell, etc.

Common type: meeting diversity needs

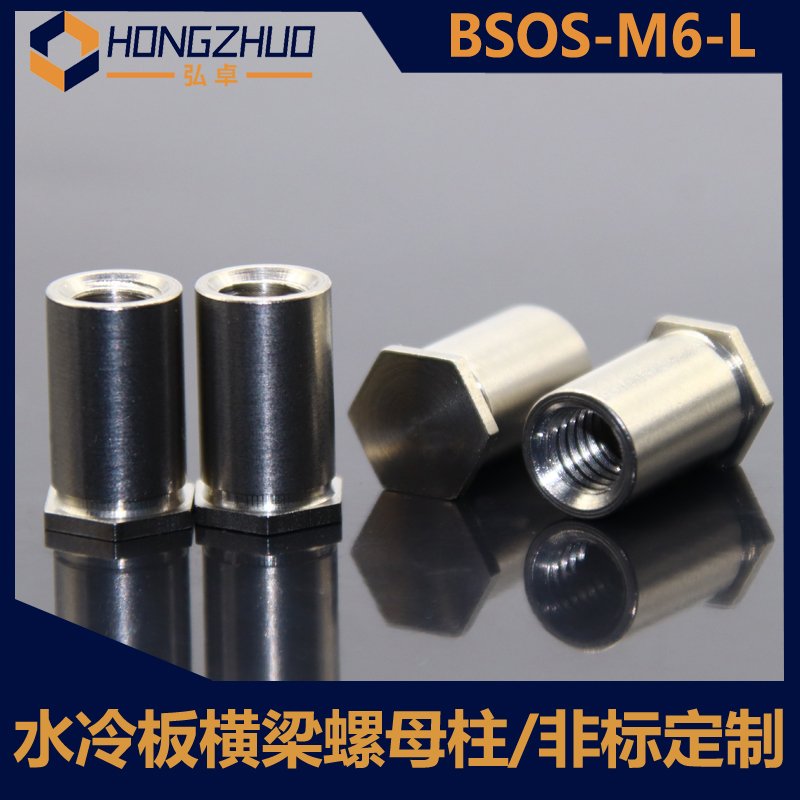

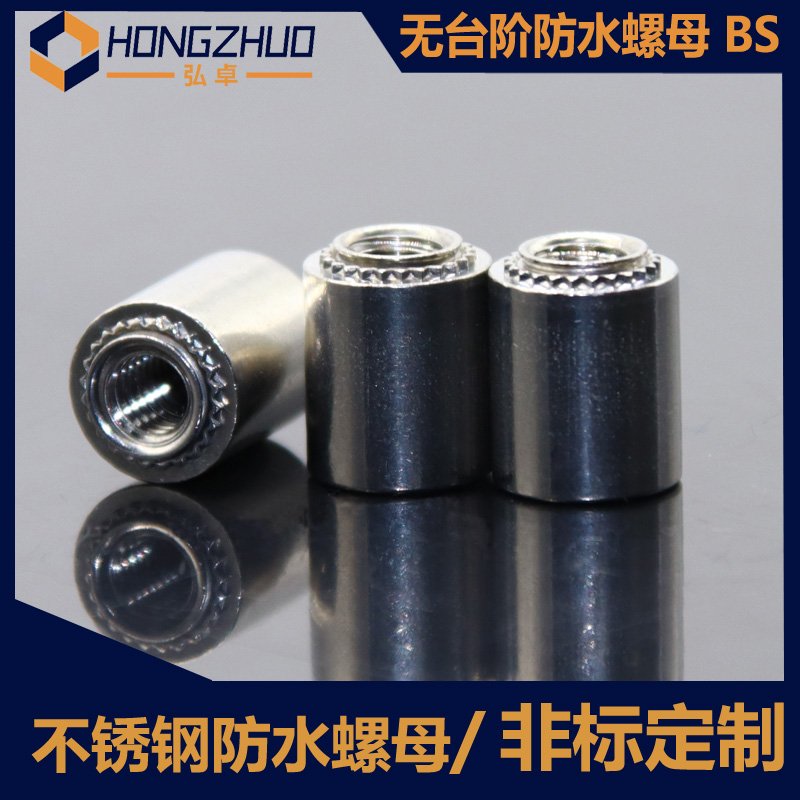

According to head shape, thread type, and function, Self-clinching fasteners can be divided into the following common types:

According to head shape: flat head, round head, heavy head, convex head, hexagonal head, etc.

According to thread type: common Self-clinching fasteners, self-drilling Self-clinching fasteners, self-cutting Self-clinching fasteners.

According to function: SEAL Self-clinching fasteners, anti-loose Self-clinching fasteners, insulation Self-clinching fasteners, etc.

The user can choose the suitable type of Self-clinching fasteners according to the specific application requirements.

4. Selection guidelines: ensure proper application

To give full play to the performance of Self-clinching fasteners, the following points should be paid attention to when selecting and using them:

Material Selection: screw material matching with the material to be connected, such as stainless steel screw for stainless steel plate, aluminum screw for aluminum plate, etc.

Screw size: select the appropriate screw size, screw diameter should be larger than the aperture, but not too large, so as not to damage the material.