Advantages of Self Clinching Threaded Studs in Manufacturing

In the world of manufacturing, efficiency and reliability are key. Fastening solutions play a crucial role in achieving these goals. Self clinching threaded studs are a standout option. They offer a robust and permanent solution for thin sheet metal applications.

These studs are designed to provide strong threads without the need for welding. This reduces potential heat distortion and material weakening. They are versatile, available in various materials to suit different environments.

Compared to traditional threaded inserts and metal studs, self clinching threaded studs offer superior performance. They are ideal for high-stress applications, providing high torque-out and push-out resistance. Their installation is straightforward, requiring no special skills.

Manufacturers across industries, from automotive to electronics, benefit from these studs. They simplify the fastening process, reduce assembly time, and lower labor costs.

What Are Self Clinching Threaded Studs?

Self clinching threaded studs are innovative fastening solutions used in modern manufacturing. They are designed to provide threads in thin sheet metal without welding. This helps maintain the integrity of the material and enhances durability.

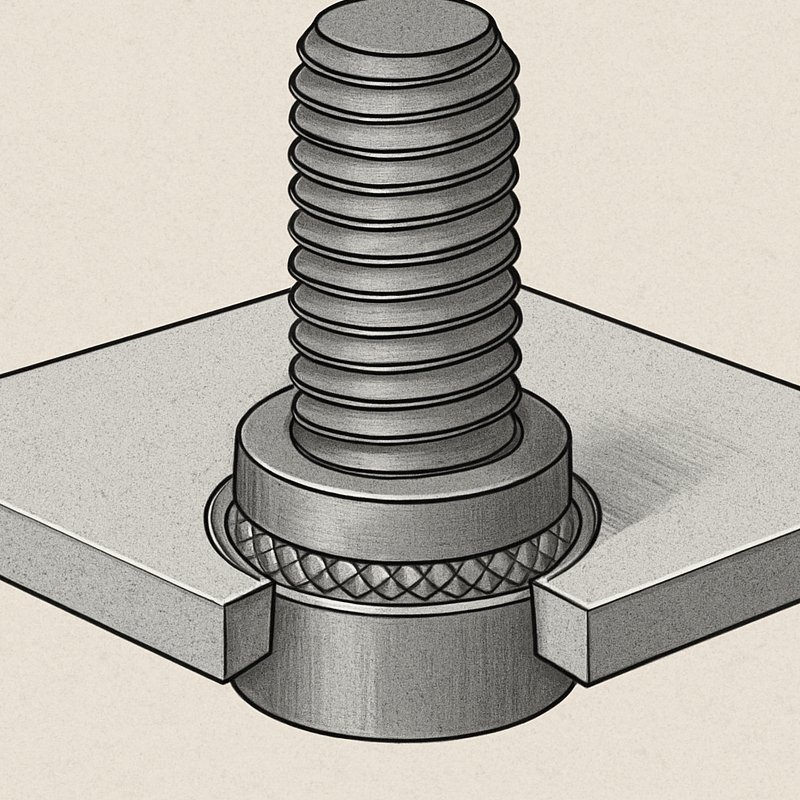

These studs are installed by pressing them into a pre-punched hole. During installation, the metal flows into a specially designed groove, securing the stud in place. This creates a strong, permanent hold, making them suitable for demanding environments.

Key features include:

- Available in various materials like stainless steel and aluminum

- Offer high torque-out and push-out resistance

- Provide a flush finish for a smooth surface

Self clinching threaded studs are versatile. They cater to diverse applications, often found in industries like automotive, aerospace, and electronics. Their ability to withstand vibration and dynamic loads makes them a popular choice in manufacturing.

How Self Clinching Threaded Studs Work

The operation of self clinching threaded studs is both simple and effective. These studs leverage the material’s natural properties to form a strong, permanent bond. The installation process is quick, ensuring efficiency in manufacturing.

When pressed into a pre-punched hole, the metal deforms into an annular groove in the stud. This deformation locks the stud securely in place. The result is a fastening solution that resists torque-out and push-out forces.

Key steps in the process include:

- Preparing the sheet with a pre-punched hole

- Placing the stud in the hole

- Applying pressure for secure installation

Such reliable performance makes these studs ideal for high-stress environments. Their ability to hold firmly without welding enhances the strength and durability of the assembly.

Key Advantages Over Other Fastening Solutions

Self clinching threaded studs present distinct advantages over traditional fastening options. They provide a durable and secure connection, which is crucial in many industries. This includes the automotive, aerospace, and electronics sectors.

One of the major benefits is the elimination of welding. This minimizes potential heat distortion and material weakening. Additionally, they offer high resistance to both torque-out and push-out, ensuring reliable performance.

Here are some advantages to consider:

- Flush finish on the opposite side, preserving the aesthetic

- Reduced assembly time and costs due to simplified processes

- Minimal space requirement as no extra nuts or washers are needed

These features make them particularly useful for applications where space is at a premium. Moreover, self clinching studs distribute load evenly, enhancing the structural integrity of the assembly.

In comparison to threaded inserts and metal studs, they provide a permanent fastening solution. This is ideal for applications requiring high precision and durability.

Notably, they also contribute to sustainability. By reducing material waste and avoiding additional surface treatments, the manufacturing process becomes more eco-friendly.

Here’s a quick recap of the benefits:

- Versatility in different environmental conditions

- Compatibility with both ferrous and non-ferrous metals

These characteristics make self clinching threaded studs a preferred choice in modern manufacturing.

Comparison: Self Clinching Threaded Studs vs. Threaded Inserts and Metal Studs

Choosing between self clinching threaded studs, threaded inserts, and metal studs depends on specific needs. Each serves unique purposes in the manufacturing industry.

Self clinching studs excel in offering a permanent and strong connection. They are favored when high torque resistance is crucial. These studs are also ideal for thin sheet metal applications without needing extra hardware.

Threaded inserts, on the other hand, are versatile but require larger holes. They offer repair capabilities if threads get damaged. This makes them suitable for materials where re-threading might be necessary.

Metal studs serve well in heavy-duty applications. They provide strength and support in structural assembly. However, they often require additional components like nuts or washers.

Consider the following when choosing:

- Torque resistance

- Material thickness

- Repair and maintenance needs

Self clinching studs typically suit applications needing high durability and minimal maintenance. Their installation is straightforward and doesn’t demand advanced skills or tools.

In conclusion, understanding the specific requirements of your project can guide the choice among these options.

Common Applications in Manufacturing

Self clinching threaded studs find widespread use across diverse industries. Their adaptability and strength make them a reliable choice for many applications.

In the automotive sector, these studs are essential. They provide secure connections in panels and assemblies, reducing weight while maintaining strength. This efficiency is critical in optimizing vehicle performance.

Electronics and telecommunications also heavily rely on self clinching studs. These industries require components that ensure the longevity of sensitive equipment. These studs offer a durable solution, withstanding vibration and dynamic loads.

The versatility of self clinching threaded studs makes them suitable for:

- Automotive parts and panels

- Electronic device housings

- Aerospace applications

- Telecommunications equipment

By employing these studs, manufacturers achieve efficient and robust assemblies, enhancing the overall quality of their products.

Installation Process and Best Practices

The installation of self clinching threaded studs is straightforward, offering simplicity and efficiency. These studs require a pre-punched hole and a standard press for proper insertion. Upon applying pressure, the metal flows into an annular groove, securing the stud.

For optimal results, following best practices is crucial. Ensure that the hole specifications match the stud’s design. This precision helps avoid installation failures or weak joints. Regular maintenance of press equipment is also necessary to maintain consistent quality.

Key best practices include:

- Use the correct hole size.

- Maintain press equipment regularly.

- Ensure proper alignment during installation.

By adhering to these best practices, manufacturers can enhance the reliability and durability of self clinching threaded studs in assemblies.

Selecting the Right Self Clinching Threaded Stud for Your Application

Choosing the correct self clinching threaded stud is crucial for effective performance. Consider factors such as material compatibility and environmental conditions. Your selection must align with the specific demands of your application.

Consider the following when selecting a stud:

- Material of the sheet and stud

- Environmental conditions (temperature, humidity)

- Load requirements and stress factors

Assessing these factors ensures the stud meets your project’s needs. This meticulous selection process enhances performance and longevity in challenging environments.

Conclusion: Enhancing Manufacturing with Self Clinching Threaded Studs

Self clinching threaded studs are essential for strong, reliable connections in manufacturing. They enhance efficiency and performance, offering a durable solution across various industries and applications.