Advantages of Self Clinching Threaded Studs

Self clinching threaded studs are a game-changer in fastening solutions. They offer a reliable and efficient way to create strong, permanent threads in thin sheet metal.

These studs are designed to simplify assembly processes. They eliminate the need for welding or additional hardware, making them a preferred choice in many industries.

Their installation is quick and cost-effective. This reduces labor costs and production time, which is crucial in today’s fast-paced manufacturing environment.

Self clinching threaded studs are versatile. They are used in automotive, aerospace, electronics, and telecommunications industries, among others.

Their ability to provide a clean, professional appearance while ensuring structural integrity makes them an ideal choice. They are a smart solution for modern engineering challenges.

What Is a Self Clinching Threaded Stud?

Self clinching threaded studs are unique fasteners designed for thin sheet metal applications. They provide robust threads by embedding themselves into the metal. This self-clinching feature makes them distinct from other types of fasteners.

These studs are typically installed through a pressing process that involves a pre-punched hole. As they are pressed in, the metal flows into a specially designed annular groove. This creates a secure, permanent fit.

Some key characteristics of self clinching threaded studs include:

- High torque-out resistance

- Strong push-out resistance

- Capability for use in blind or through-hole applications

Their specific design offers several advantages over other traditional methods, such as welding. The versatility and reliability of these studs make them suitable for a wide range of applications.

How Self Clinching Threaded Studs Work

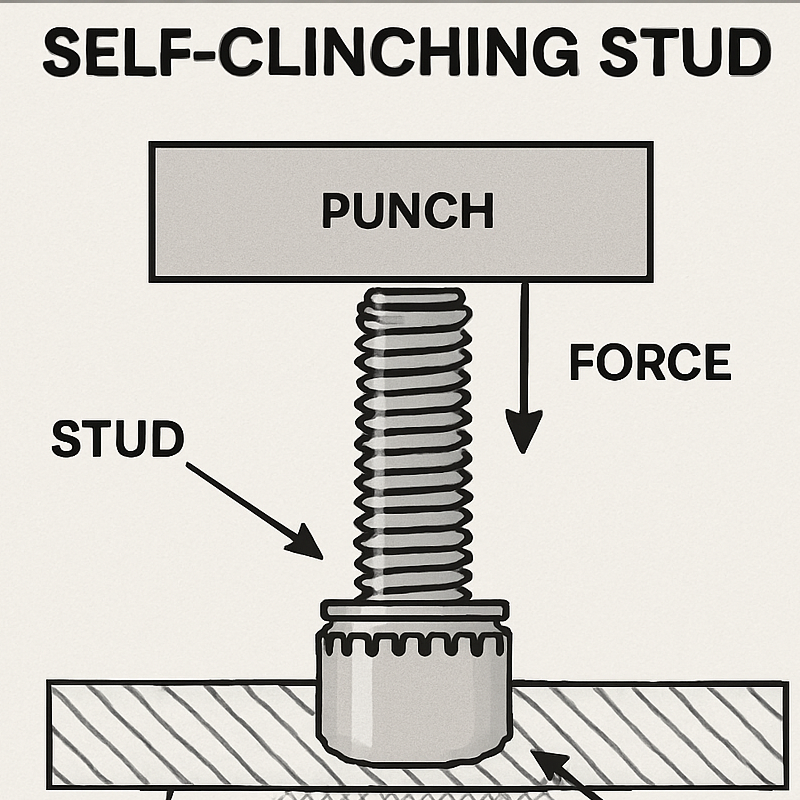

The operation of self clinching threaded studs is straightforward yet effective. They are pressed into a pre-punched hole in a sheet of metal. As pressure is applied, the surrounding metal deforms to fill the stud’s groove.

This deformation creates a solid lock, anchoring the stud permanently. Thus, these studs offer a non-slip solution that does not require additional fastening components. The outcome is secure fasteners without the need for drilling or machining threads.

Some core benefits of this mechanism include:

- Simplified installation

- Secure locking mechanism

- No need for extra fastening components

In practice, this process is typically completed with standard press equipment. The simplicity of their installation helps reduce labor and production costs. Overall, this makes self clinching threaded studs a cost-effective choice in manufacturing.

Key Advantages Over Other Fastening Solutions

Self clinching threaded studs stand out due to their unique benefits. They provide high torque-out and push-out resistance, ensuring durability. These features make them reliable in challenging conditions where standard fasteners might fail.

Another advantage is the elimination of welding or extra hardware. This reduces the complexity of assembly processes. Consequently, manufacturers experience easier installation and lower production costs.

These studs also offer a flush finish, which is crucial in applications with limited space. The lack of protrusions improves aesthetics and functionality in constrained environments. They are designed to stay secure, even under vibrations and dynamic loads.

A concise list of advantages includes:

- High torque and push-out resistance

- No need for welding or extra hardware

- Flush finish in limited spaces

- Reliable under vibrations

- Cost-effective and simple installation

Importantly, self clinching threaded studs integrate well with automated systems. They enhance production efficiency, as they can be quickly installed. Their design is versatile, fitting both blind and through-hole applications.

These self clinching options improve structural integrity, reducing assembly weight. Choosing them offers numerous benefits over traditional fastening solutions, ensuring high-performance results.

Common Applications and Industries

Self clinching threaded studs are versatile, used across multiple industries. They meet the demands of automotive and aerospace sectors. These industries require components that can endure stress and vibrations.

Electronics and telecommunications also rely heavily on these studs. They ensure secure attachments in devices where precision is vital. The clean finish enhances the product’s aesthetic, adding value to the final design.

Industries benefiting from self clinching threaded studs include:

- Automotive

- Aerospace

- Electronics

- Telecommunications

Moreover, they find applications in any metalworking field needing durable and efficient fastening. They support processes where long-term reliability is crucial. These studs help maintain structural integrity, even under harsh conditions.

Material Options and Customization

Self clinching threaded studs come in a range of materials to meet specific needs. This variety ensures they adapt to diverse environments and applications. Common materials include stainless steel, aluminum, and zinc-plated steel.

These options provide different benefits, like corrosion resistance or light weight, depending on the material used. The choice of material affects durability and suitability for particular conditions.

Customization is another key advantage. Manufacturers can choose thread sizes, lengths, and material types to fit unique requirements. Options for customization help meet specific design and application needs, making self clinching threaded studs a tailored solution for various projects. This flexibility ensures they remain a preferred choice in many industries.

Installation Process and Efficiency

The installation of self clinching threaded studs is both simple and efficient. It involves pressing the stud into a pre-punched hole. This allows the metal to flow into a designed groove.

This method requires no welding or additional hardware, streamlining the process. The ease of installation reduces labor costs and speeds up production.

Key benefits of the installation process include:

- Quick and straightforward setup

- No need for complex equipment

- Compatibility with automated systems

These studs can be installed using standard press equipment. This makes them accessible for various manufacturing operations. Their efficient installation process is a significant advantage, promoting faster assembly without compromising quality.

Comparing Self Clinching Threaded Studs to Threaded Inserts and Welded Studs

Self clinching threaded studs offer distinct advantages over threaded inserts and welded studs. They provide a stronger, more permanent hold. They also require less preparation and finishing.

Unlike threaded inserts, self clinching studs are ideal for use in thin metals. This ability to function efficiently in limited space sets them apart. In contrast, welded studs demand extra equipment and can distort metal.

Key comparisons include:

- Less equipment needed than for welded studs

- More permanent than threaded inserts

- Suitable for thin sheet metal applications

These studs eliminate the need for adhesives or additional chemicals. This makes them an eco-friendly choice. They provide a more streamlined and durable fastening solution.

Conclusion: Why Choose Self Clinching Threaded Studs?

Self clinching threaded studs stand out as efficient fastening solutions for various industries. Their strength and ease of installation offer significant advantages over traditional methods.

By choosing these studs, manufacturers can enjoy reduced costs and improved assembly efficiency. Their versatile application and environmentally friendly nature make them an excellent choice for modern fabrication needs.