Advantages of Self Clinching Stud Fasteners

Self clinching stud fasteners are a game-changer in the world of metal assembly. They offer a reliable solution for creating strong, permanent threads in thin materials. These fasteners are designed to be permanently mounted in thin sheet metal. This makes them ideal for applications where space is limited.

The installation process is simple and efficient. It involves pressing the stud into a pre-punched hole. This causes the metal to flow into a specially designed annular groove. No welding is required, reducing the risk of heat distortion.

Self clinching studs are versatile and can be used in various industries. They are commonly found in automotive, electronics, and aerospace applications. Their ability to provide a flush finish makes them aesthetically pleasing.

These fasteners are available in different materials, including stainless steel and aluminum. They offer high torque-out and push-out resistance, ensuring a secure hold. This makes them suitable for applications where vibration resistance is important.

The use of self clinching studs can reduce assembly time and costs. They eliminate the need for additional hardware, making them a cost-effective choice. Their design allows for easy disassembly and reassembly of components. This is particularly beneficial for applications requiring frequent maintenance or part replacement.

What Are Self Clinching Stud Fasteners?

Self clinching stud fasteners are specialized components used for securing items to thin sheets of metal. They are engineered to provide strong, reusable threads where standard fastening methods fall short. By design, these fasteners create a secure, permanent connection with the material they are installed in.

The process of installing a clinch stud begins with pressing it into a pre-drilled or punched hole in the sheet metal. During this action, the metal flows into an annular groove on the fastener. This mechanical interlock ensures the stud is securely embedded.

One of the significant advantages is that these fasteners do not require welding. This eliminates concerns of heat distortion, which can compromise the integrity of the material. Additionally, self clinching studs provide a clean, flush finish ideal for applications needing a smooth surface.

These fasteners are available in various sizes and materials. Common choices include stainless steel, aluminum, and zinc-plated steel. This diversity allows them to be used in numerous environments and conditions.

Key features of self clinching stud fasteners include:

- Permanent thread creation

- Ease of installation without special tools

- Compatibility with thin materials

- Secure, vibration-resistant hold

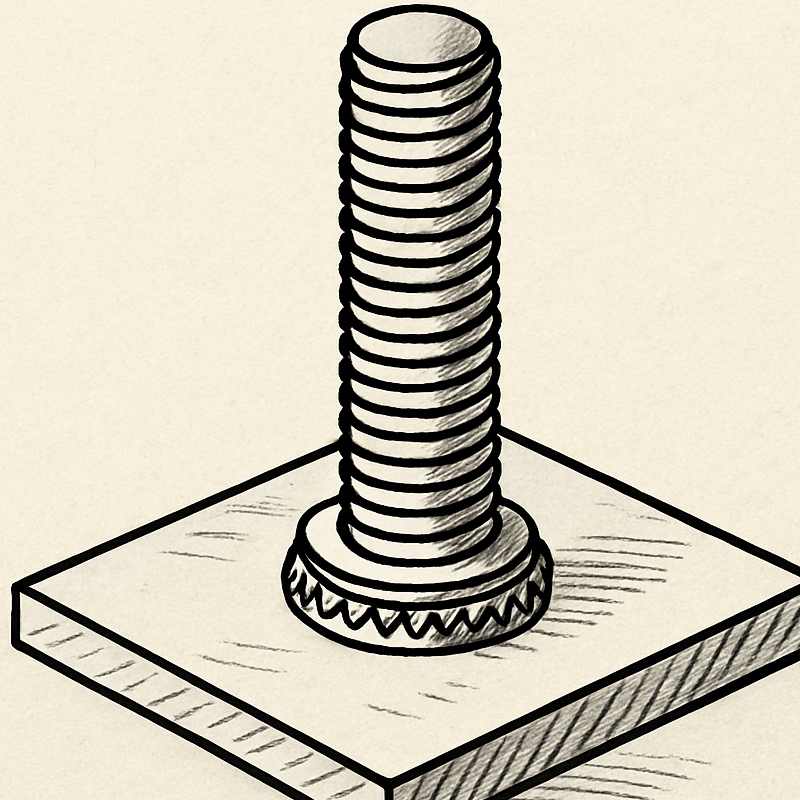

Here’s what a typical self clinching stud fastener looks like:

How Do Self Clinching Studs Work?

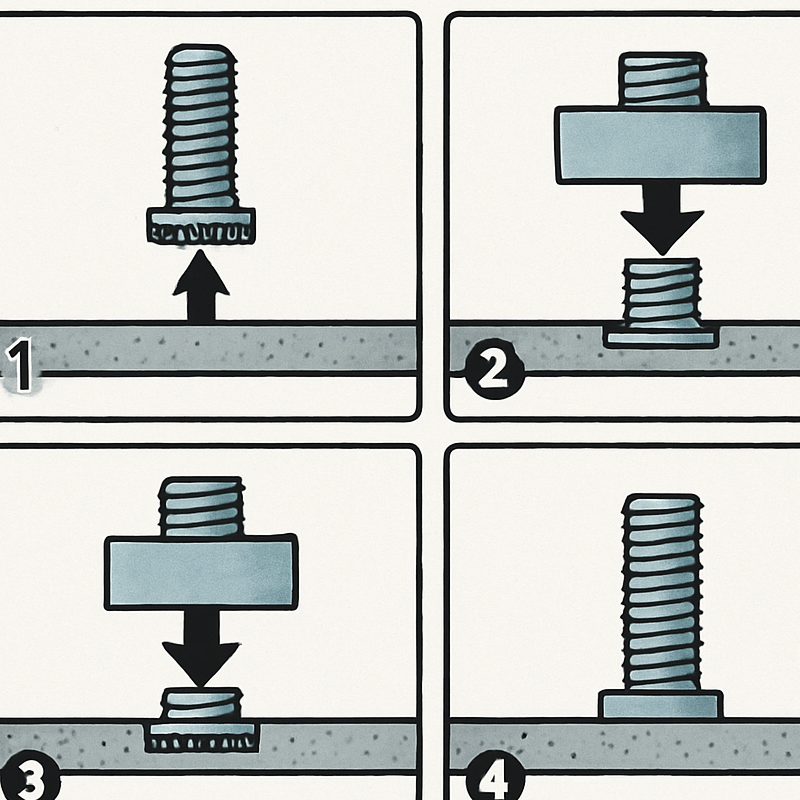

The function of self clinching studs begins with a simple yet effective installation process. This involves inserting the stud into a pre-punched hole within a sheet metal surface. The stud features a specially designed head and an annular groove.

When pressure is applied, the sheet metal deforms into the groove. This mechanical locking mechanism secures the stud without additional fasteners. The design leverages the metal’s natural properties to achieve a firm hold.

One key aspect is the tool’s simplicity. Installation requires minimal equipment, ensuring efficiency across various settings. As the process doesn’t involve heat, it mitigates any risks associated with thermal distortion.

Benefits of the locking mechanism include:

- High torque-out resistance

- Superior push-out resistance

- Secure and permanent fastening

Self clinching studs are engineered for durability. The embedded design reduces potential points of failure, giving these fasteners longevity under load.

Ultimately, this method provides a robust solution for creating reliable attachment points in thin materials. It’s ideal for applications where consistent and dependable fastening is crucial.

Here’s an illustration showing the installation process of a self clinching stud:

Key Advantages of Self Clinching Stud Fasteners

Self clinching stud fasteners are celebrated for their remarkable benefits. They provide a secure, permanent attachment in metals too thin for traditional tapping. This makes them indispensable in many industries.

A primary advantage is their ability to streamline assembly processes. They reduce the need for extra hardware, saving both time and cost. Simplifying the assembly can lead to increased productivity and efficiency in production lines.

These fasteners offer high torque resistance. Their design ensures that once installed, they resist both torque-out and push-out forces. This adds to the durability and security of the assembly.

Another significant advantage is the clean, flush finish they provide. This aesthetic benefit is especially valued in products where appearance matters. With no protruding parts, the end product looks sleek and professional.

Additional notable advantages include:

- Quick and simple installation

- Reduced risk of heat-induced distortions

- Minimal installation equipment needed

The resistance to vibrations is also paramount. In industries like automotive and aerospace, this ensures the fasteners hold steady under dynamic conditions. This reliability is crucial for safety and performance.

Here are more benefits to consider:

- Environmentally friendly installation, no chemicals needed

- Enhanced corrosion resistance with suitable coatings

- Compatibility with various materials and finishes

An added benefit is their versatility. Available in a range of sizes, lengths, and materials, they are suitable for diverse applications. This adaptability helps meet the global standards required by many industries.

For a visual understanding, consider this image highlighting these advantages:

These fasteners’ unique combination of durability, efficiency, and aesthetic appeal makes them the preferred choice for many applications. They deliver not only practicality but also the reliability needed in modern manufacturing.

Types of Self Clinching Studs

Self clinching studs come in various forms, each tailored to specific needs. They offer solutions for different thicknesses and materials, expanding their versatility.

One primary type is the flush-head stud, ideal for flat surfaces. Its design allows for a seamless finish, making it popular in applications where aesthetics are crucial.

Another variant is the blind standoff stud. This type is excellent when backside access is limited. It provides a secure fastening without compromising the surface appearance.

There are also non-flush studs. These are designed for situations where a protruding surface is acceptable. They are often used when precise alignment is required.

To break it down, here are some common types:

- Flush-head studs

- Blind standoff studs

- Non-flush studs

Each type serves distinct applications, offering engineers and designers a range of options. Understanding their specific uses helps in selecting the right stud for the job.

Consider this image to visualize the differences among various self clinching studs:

By choosing the appropriate type, manufacturers can enhance both the functionality and appearance of their products. These options contribute to the growing popularity of self clinching solutions.

Materials and Finishes for Clinch Studs

Self clinching stud fasteners are crafted from various materials to meet diverse requirements. The choice of material impacts durability, strength, and corrosion resistance.

Stainless steel is a popular option due to its robustness and rust-resistant properties. It’s ideal for harsh environments where longevity is crucial. Aluminum clinch studs offer a lightweight alternative while maintaining respectable strength. They are suitable for applications where weight is a concern.

Zinc-plated steel is another common choice. The zinc coating provides an added layer of protection against corrosion. This makes it favorable for outdoor or high-moisture environments.

Available material options include:

- Stainless steel

- Aluminum

- Zinc-plated steel

Finishes also play a crucial role in the performance of clinch studs. They enhance the visual appeal and extend the life span of the fasteners. Coatings and finishes can be adjusted based on specific aesthetic and functional needs.

Here’s an image illustrating various material finishes for clinch studs:

Selecting the right combination of material and finish ensures the best performance and longevity in your application. Different industries benefit from these tailored solutions, optimizing their products for specific conditions.

Applications Across Industries

Self clinching stud fasteners are widely used in various industries. Their versatility makes them a go-to solution for multiple applications. These studs offer a reliable and efficient way to secure components in different sectors.

In the automotive industry, clinch studs are often utilized to attach panels securely. This helps in maintaining the structural integrity of vehicles. Similarly, the electronics industry benefits from self clinching studs in assembling enclosures and circuit boards.

Aerospace applications demand high-performance fasteners, and clinch studs are ideal due to their strong hold and lightweight nature. Their ability to resist vibration ensures that they remain secure in demanding environments.

In the telecommunications industry, self clinching studs are used to fix equipment panels and housings. Their ease of installation makes them a cost-effective solution for high-volume assembly lines.

Common applications include:

- Automotive panel assembly

- Electronic enclosures

- Aerospace components

- Telecommunications housing

By serving a variety of industries, self clinching studs prove their adaptability and importance. These fasteners not only meet but exceed the expectations of engineers and manufacturers.

Self Clinching Studs vs. Other Fastening Methods

Choosing the right fastening method is critical in product design and assembly. Self clinching studs offer several benefits over traditional techniques. They stand out for their simplicity and reliability.

Welding is a common fastening method, but it can cause heat distortion. This affects the integrity of metal parts. In contrast, self clinching studs avoid this by using cold pressing techniques. This keeps the material’s original properties intact.

Riveting is another popular method. It involves using additional components, which increases costs. Self clinching studs eliminate the need for extra hardware, making them cost-efficient.

Bolting requires precise alignment and access to both sides of the assembly, which isn’t always possible. Clinch studs, however, are installed from one side, simplifying the process.

Comparative advantages of self clinching studs over welding:

- No heat distortion

- Maintains material properties

Comparative advantages over riveting and bolting:

- Reduces component count

- One-sided access for installation

By choosing self clinching studs, manufacturers can save time and lower costs. Their ease of use and reliability makes them a preferred choice for modern assembly needs.

Installation Process and Best Practices

The installation of self clinching studs is a straightforward process. It involves pressing the stud into a pre-punched hole in the metal sheet. This technique secures the stud permanently in place.

To achieve optimal results, it’s important to follow some best practices. First, ensure the hole is clean and free of debris. This promotes effective metal flow into the stud’s groove.

Proper alignment is crucial for successful installation. Misalignment can lead to poor seating and diminished strength. Use guides or fixtures to maintain accurate positioning.

Another important aspect is the application of consistent pressure. This ensures the metal flows evenly around the stud. Automation can help achieve uniformity in high-volume production.

Best Practices for Installation:

- Clean the hole thoroughly

- Align stud carefully

- Apply consistent pressure

- Use automation for large batches

By adhering to these best practices, manufacturers can maximize the performance and durability of self clinching stud fasteners. This results in a robust and reliable fastening system.

Common Challenges and Solutions

Despite their benefits, self clinching studs can present challenges during installation or use. Incorrect hole sizing is a frequent issue. Too small or too large holes can result in weak connections.

Misalignment during installation also poses a challenge. This can lead to reduced stud integrity and inefficiency. Maintaining precision is key to avoiding this problem.

Engaging with these challenges effectively involves understanding their solutions. Ensuring optimal conditions and precision will help.

Common Challenges and Solutions:

- Incorrect hole size: Verify dimensions before punching.

- Misalignment: Utilize alignment guides and fixtures.

- Uneven pressure: Implement automated pressing systems for consistency.

Staying informed about these potential hurdles allows manufacturers to employ effective solutions. Addressing these issues ensures the reliable performance of self clinching stud fasteners across diverse applications.

Frequently Asked Questions About Self Clinching Studs

Many potential users have questions about self clinching studs. Understanding these can help in selecting the right fastening solution.

One common question is about compatibility with different materials. Self clinching studs work with a variety of metals, including both ferrous and non-ferrous options.

Another frequent inquiry is about the durability of these fasteners. Users often ask whether they can handle high-stress environments. These studs are engineered for high loads and stresses.

The installation process also attracts queries. Users want to know about the necessary tools and techniques for proper installation.

Frequently Asked Questions:

- Which materials are compatible with these studs?

- Can they handle high stress and loads?

- What tools are needed for installation?

By addressing these questions, manufacturers can better assist their customers, ensuring effective and efficient use of self clinching stud fasteners.

Conclusion: Why Choose Self Clinching Stud Fasteners?

Self clinching stud fasteners are an exceptional choice for various applications. They offer a permanent, reliable solution. Their installation process is straightforward, saving time and labor costs.

Engineers prefer these fasteners for their space efficiency and strong hold in thin materials. They don’t require any specialized tools, which makes them accessible and easy to use.

Whether you’re in the automotive or electronics industry, these fasteners will enhance product performance. They provide a clean finish, high durability, and cost-effectiveness. Opting for self clinching stud fasteners ensures that you receive a versatile and robust solution suitable for a broad range of applications.