Why would an airplane choose to conect with millions of rivtes, not to choose welding?

If we look closely at the

If we look closely at the

In the process of sheet metal parts, it is common to press riveting stud, screw, or nut on the sheet metal parts to meet the use function of the parts. In addition to stainless steel, the surface of most sheet metal parts needs plating treatment, pressure riveting fasteners electroplating, easy to lose, fall off, and other phenomena, that affect the quality of pressure riveting.

The main issues for design engineers to consider are the following: Bend/ Puchong/ Fitter/ Press riveting/ Welding/ Spray

With the development of the economy and the renovation of various technologies, riveting technology has been gradually applied in the sheet metal industry. Among them, clinch nut, and clinch screw is the most common, it rivets firmly, high efficient, easy to use. In a certain range, it has replaced some traditional welding processing methods. But in the use process, we must pay attention to the following basic requirements

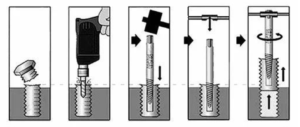

Clinch Studs and bolts are common parts of mechanical equipment, mainly used to link a variety of parts. But in the use of the process, sometimes there will be a break. In that case, what method can be skillfully taken out of the pressure-breaking clinching screws or bolts?